Deploy Logistics Operational Dashboards using DataPane

Deploy Reporting Solutions using DataPane to Support Warehousing Logistics Operations for E-Commerce.

Build reporting capabilities to provide supply chain visibility and support the operational teams of a Distribution Center of a mid-size retailer

In some markets like China, the retail industry has been completely disrupted by E-Commerce. The rapidly changing consumer behaviours have dramatically changed the way these companies manage their business.

This directly impacts the Logistics Operations of these retailers that now face high volatility of volumes, larger portfolios of products and very short lead times.

Build Data Analytics Capabitilities for Small Businesses

However, SMEs (Small and Medium Enterprises) may not have the budget to invest in expensive data infrastructures to build reporting capabilities.

In this article, we will design a simple architecture to deploy an interactive dashboard for Warehousing Operations using the Python Library DataPane.

💌 New articles straight in your inbox for free: Newsletter

I. Context: Warehousing Operations for E-Commerce

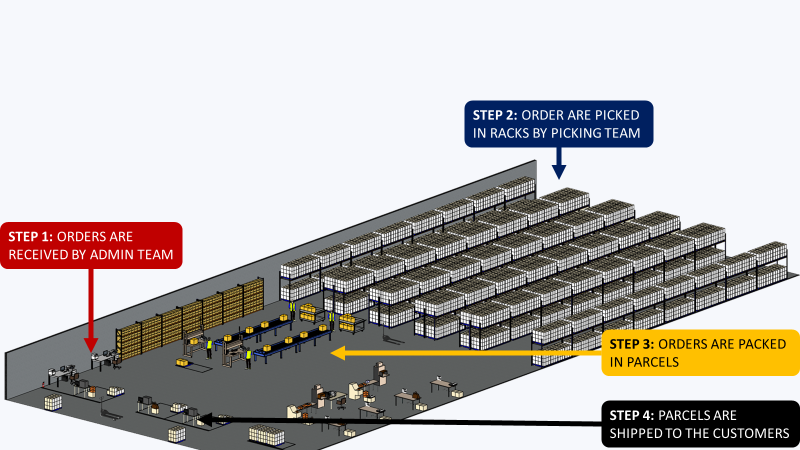

Warehouse to prepare and ship orders for an E-Commerce website

ObjectiveHow can you support Operational Excellence with simple reports

II. Build reports using DataPane

1. Quick IntroductionDeploy and share your results with Datapane

2. Monitor the picking workload

Build visuals showing the number of orders received per day

3. Analyze the volumes pareto

How many SKU are representing 80% of your volume?

III. Conclusion & Next Steps

Scenario

Problem Statement

As a Continuous Improvement Engineer in the Distribution Center (Warehouse) of a mid-size online retailer, you are in charge of building reporting capabilities to bring visibility to operational teams.

The distribution centre is in charge of order fulfilment and shipment

- Customers order products on the website

- These orders are received by the Warehouse Management System (WMS)

- Warehouse Operators prepare the orders and pack them in parcels

- Parcels are shipped to the customers

The most important Key Indicator of Performance (KPI) is the lead time between order receiving and parcel shipment.

This KPI is impacted by all the processes in the chain; you will provide visibility on the key indicators impacting the overall performance.

Build reports using DataPane

You will not build a complete cloud architecture with ETL jobs and advanced visualization tools like PowerBI, Tableau or Google Studio.

The idea is to extract data from the WMS, process your data locally and deploy reports that can be used by operational teams.

Deploy reporting capabilities with DataPane

This framework gives you the opportunity to share the results of your Jupyter notebook with your colleagues.

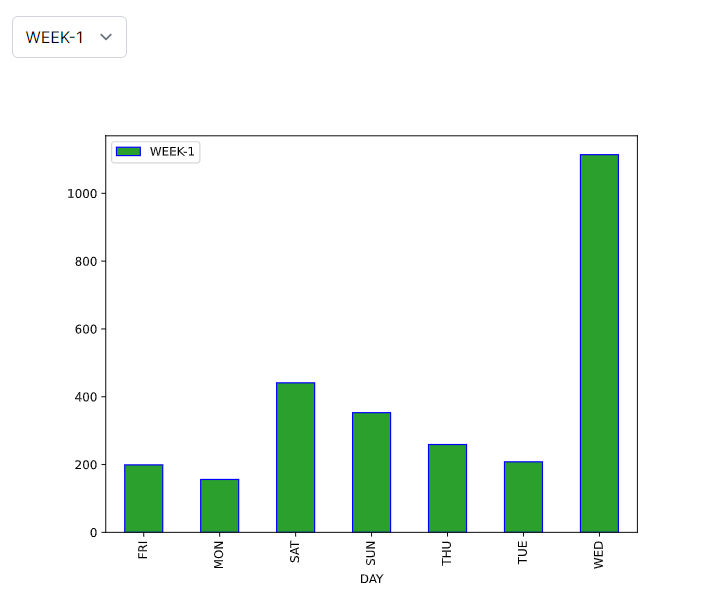

For instance, you would like to share this simple bar plot chart.

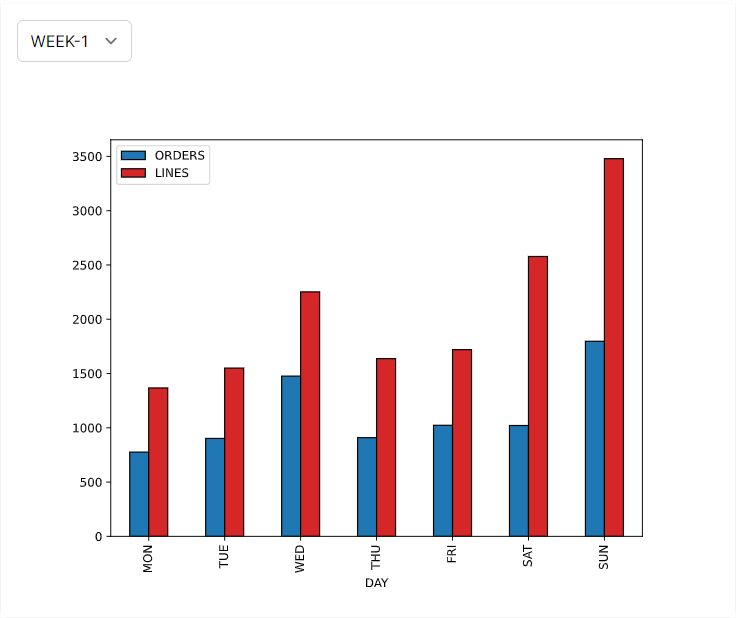

This chart shows the number of orders (and lines) received by the warehouse per day.

How can you share this graph with your colleagues?

It is a very simple process in three steps (Link)

- Get the client library using pip

2. Sign up on DataPane and register your Token

3. Deploy your visual

You need to add a section in your code to deploy your visual, you can choose several templates

4. You can share this visual with colleagues

They can even select the week with the button (top-left). This visual can be shared privately with a link that you can send to the operational teams.

Next Steps

We will now build a set of visuals, based on specific processes, to bring visibility to the teams.

Monitor your workload

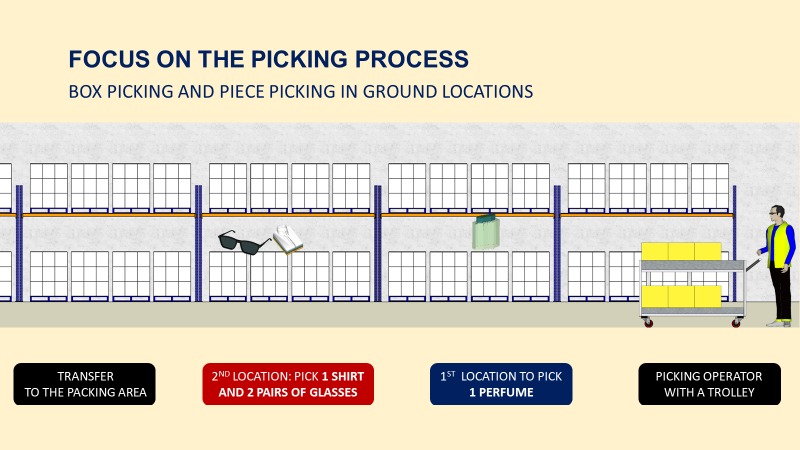

Focus on the Picking Process

Operators are taking their trolleys with a list of items ordered by the customer and will stop at each location to take the quantity ordered.

If you want to understand more about the picking process, have a look at the video below

Number of Orders/Lines

Question

How many orders (and lines) do we receive from customers every day?

A major indicator of the picking workload is the number of customers orders (and order lines).

Insights

Week-1 Sunday: picking teams faced a peak of order lines that could probably explain a bad performance this day.

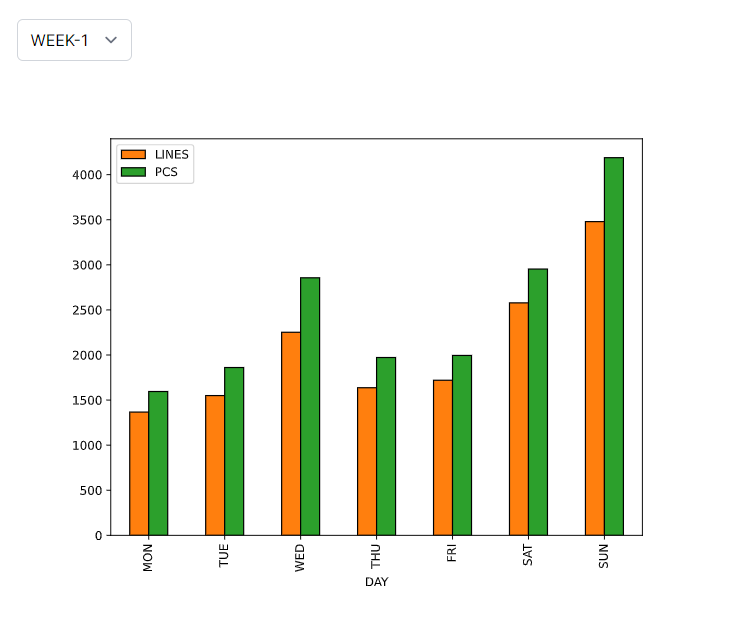

Number of Pieces per Day

Question

How many items are ordered by customers every day?

This indicator can provide visibility on the turnover of the company for that day. It is also impacting the volume (cubic meters) of parcels shipped.

Insights

Week-1 Wednesday: we experienced a surge in the number of pieces per line due to a special promotion for a certain item.

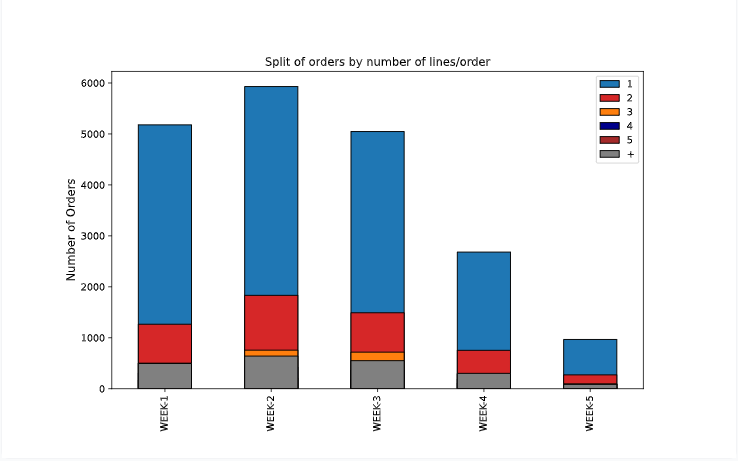

Split of orders per the ratio of line/order

Question

What is the split (%) of mono-line orders for each day?

With a high number of lines per order, your operators will see their walking distance per order increasing. Therefore, their productivity of picking is directly impacted by the number of lines per order.

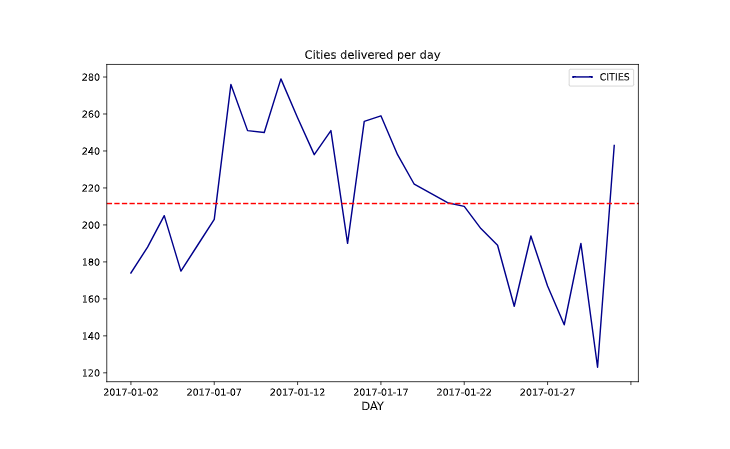

Number of Cities Delivered

Question

How many different cities do I need to deliver per day?

The number of cities delivered impacts your workload for transportation management.

Insights

We have a majority of mono-line orders (1 line/order) that can be picked by batch.

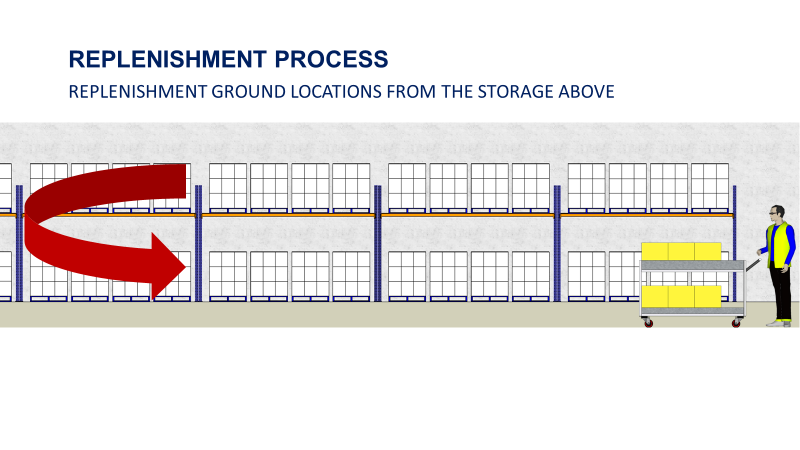

Focus on the replenishment process

When the picking locations (on the ground) are empty, your forklift drivers perform replenishments tasks.

They take items from the storage area above to replenish the picking locations for future orders.

Number of replenishments per day

Question

How many replenishments tasks are performed by your operators per day?

This process can become a bottleneck and impact your overall performance, you need to track your workload per day.

Insights

For a large part of the month, you experienced a surge of the number of cities delivered that may impact your transportation costs.

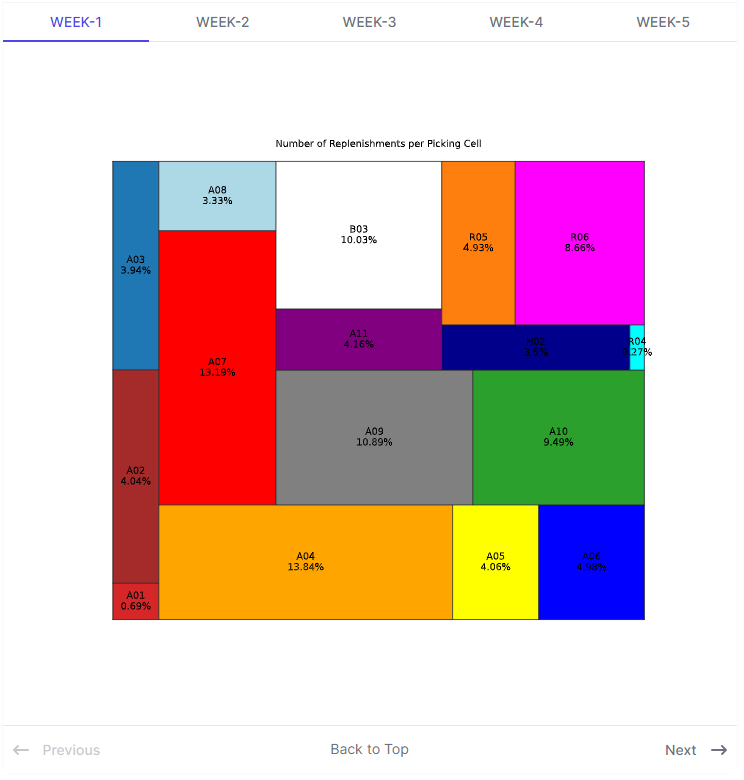

Number of replenishments per alley

Question

Which area of your warehouse concentrates the majority of your volume?

Your warehouse is organised by alleys with cells and picking locations.

A major bottleneck occurs when a concentration of people is in one area.

If you encounter this issue, the best solution is to avoid grouping high-rotation areas together.

Insights

20% of the volumes in Pieces

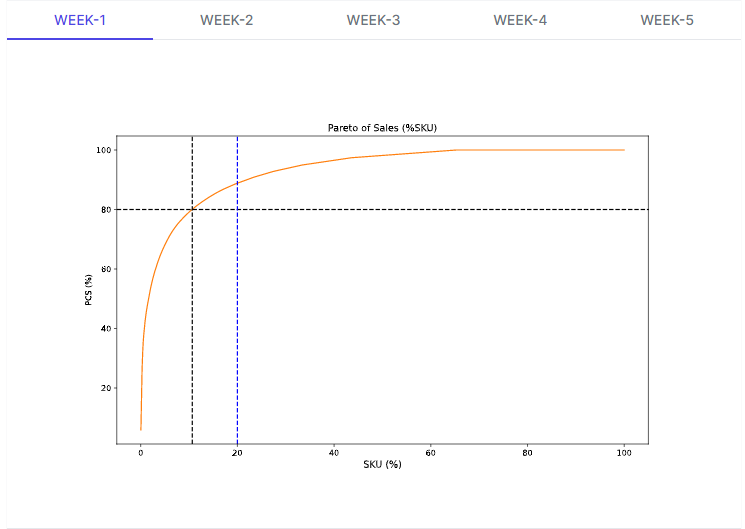

Analyse the Pareto

Question

How many SKUs are representing 80% of my total volume?

To optimize your processes you need to perform product segmentation based on the volume per item.

High rotations items need to be put in full pallet picking location while low rotations can be stored on shelves to save space.

Because the business is evolving, you need to track your Pareto to adjust your layout and processes.

If you want to understand more about the Pareto law for layout optimization, have a look at the video below

Conclusion & Next Steps

You have built a set of simple (but very useful) visuals that can be used by operational teams.

For instance, they can be embedded in a Notion document with a comments area to make it a living document.

This solution will not meet the performance and functionalities of a proper cloud architecture. However, it can be easily implemented without any additional costs for small structures.

You can deploy the code you use to build these visuals in the cloud (Heroku, Google App Engine) to automate this process and trigger tasks on a daily basis.

About Me

Let’s connect on Linkedin and Twitter, I am a Supply Chain Engineer that is using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, feel free to contact me.