How Will Data Science Accelerate the Circular Economy?

Actionable data science tips to overcome the operational challenges in transitioning to a circular economy.

Actionable data science tips to overcome the operational challenges in transitioning to a circular economy.

This article was originally published on Medium.

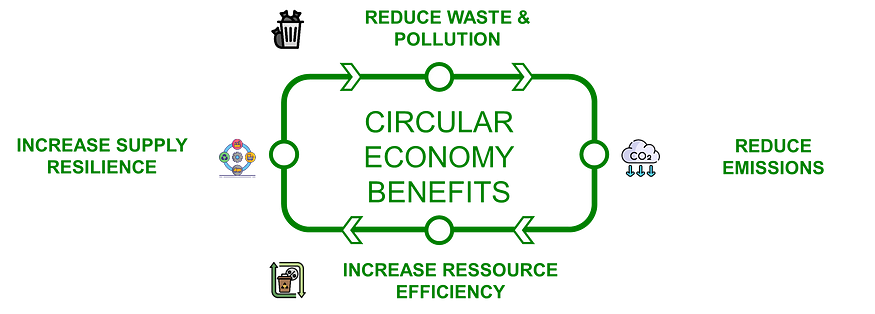

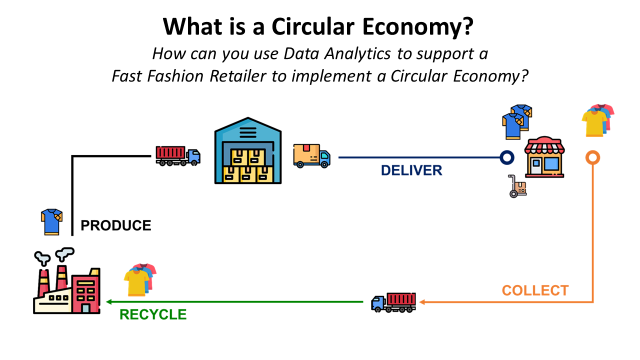

A circular economy is an economic system where waste is minimized and resources are continuously reused or recycled.

Imagine a world where your waste doesn’t end up in landfills but rather becomes the raw material for new products.

The transition from our current linear economy to a more sustainable circular one is a major topic for many companies.

What is holding us back?

As the current linear economic model reaches its limits, discussions around new circular business models become more and more prominent.

These discussions mainly focus on

- The operational and business obstacles blocking the transition

- Alternative strategies to increase the use of recycled materials

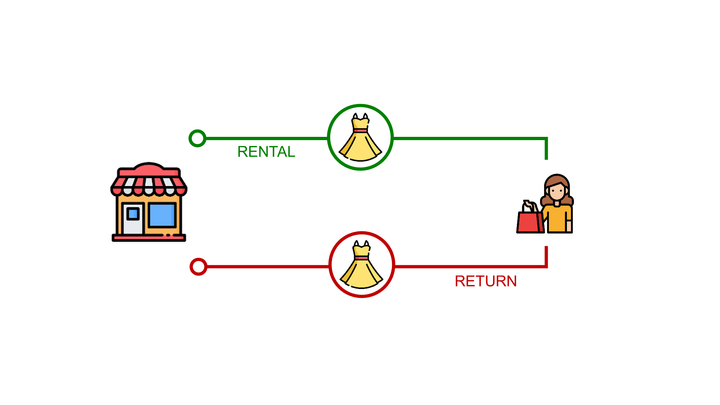

- Rental models to reduce the environmental footprint

As the analytics manager of a retail company, how can I support this transition?

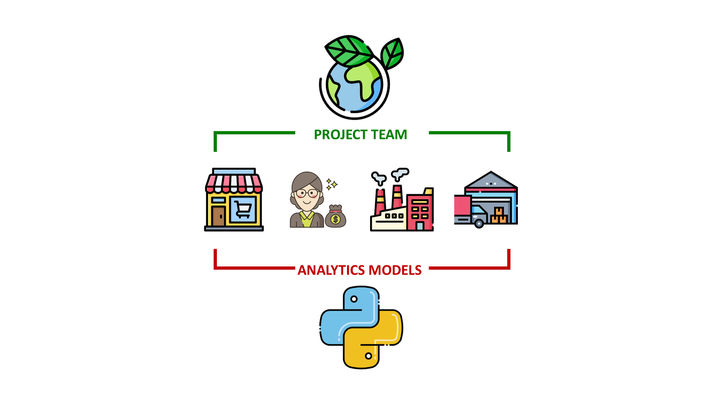

Analytics experts can leverage the data generated by systems to overcome these barriers by identifying opportunities to create a sustainable and profitable circular supply chain.

In this article, we will step into the shoes of an analytics manager who has been asked to support the operational transformation of a fashion retail company.

💌 New articles straight in your inbox for free: Newsletter

📘 Your complete guide for Supply Chain Analytics: Analytics Cheat Sheet

I. Transition to a Circular Economy

1. What is the environmental impact of a T-shirt?

2. Data-driven Process Design

II. Overcoming the Operational Challenges

1. The Opacity of Supply Chain Networks

2. The Low Residual Value of Used Products

III. Material Efficiency & Recycled Materials Usage

1. Raw Material Optimization with Linear Programming

2. Supply Chain Network Optimization

IV. Conclusion

Transition to a Circular Economy

The evolution from a linear model to a circular economy is an ongoing process with significant business and operational implications.

This shift is not just about waste management or recycling.

It requires a holistic change in how we design, produce, sell and use goods or services.

Before implementing a circular economy, the first step is to estimate the environmental impact of our current linear model.

What is the environmental impact of a T-shirt?

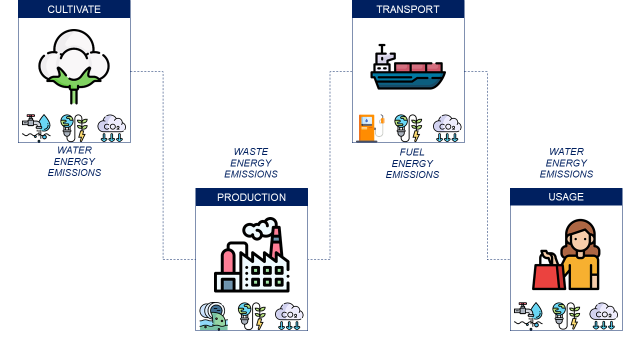

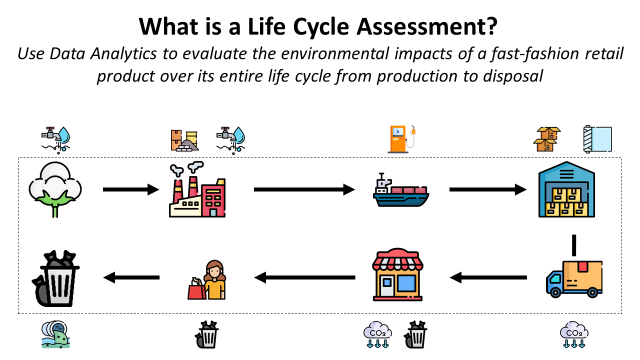

Let’s take the example of a T-shirt you bought in a fast-fashion store.

What is its environmental impact along its life cycle?

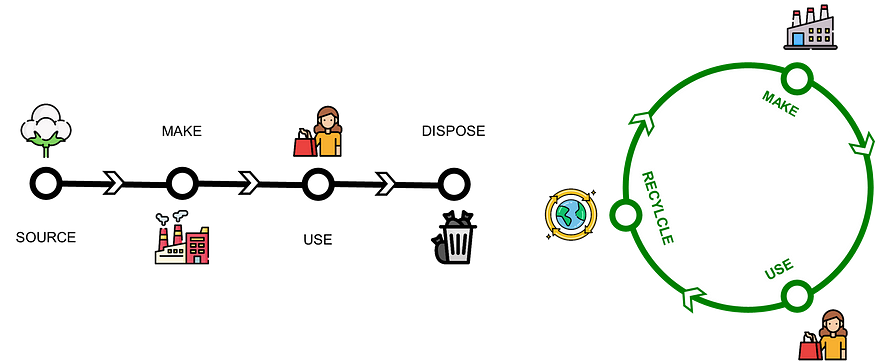

Life cycle assessment (LCA) is a methodology used to evaluate the environmental impacts of a product or service over its entire life cycle.

- Raw materials are sourced from different suppliers that are using natural resources and energy.

- Manufacturing sites transform these materials into finished products using natural resources while emitting pollutants and CO2

- Finished products are delivered to stores and sold to final customers

- Customers are using the products until disposal

How can we support the automation of Life Cycle Assessment?

This descriptive analytics methodology can be automated using Business Intelligence solutions implemented by our analytics team.

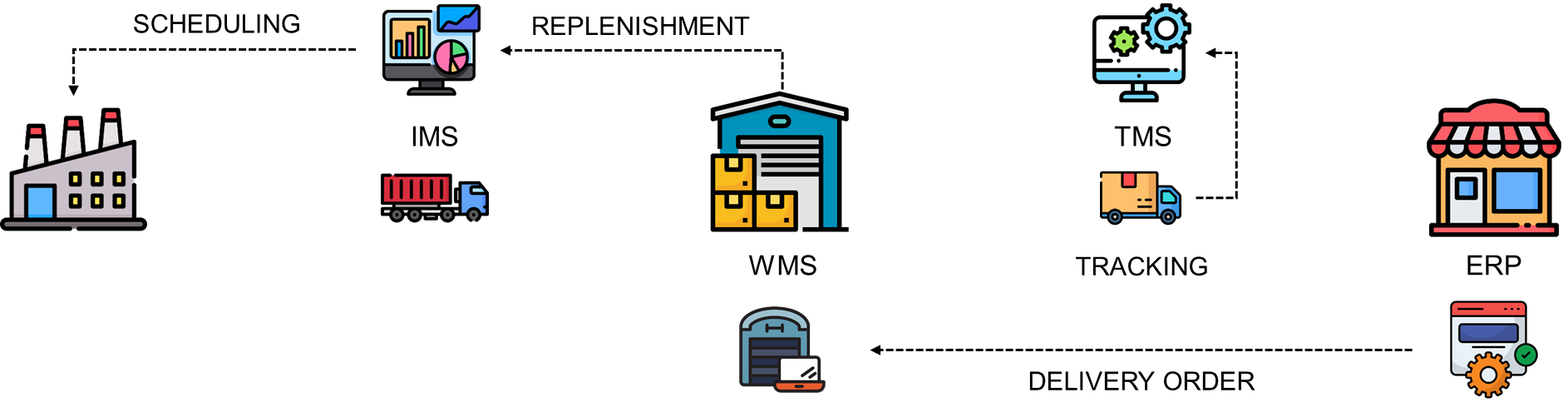

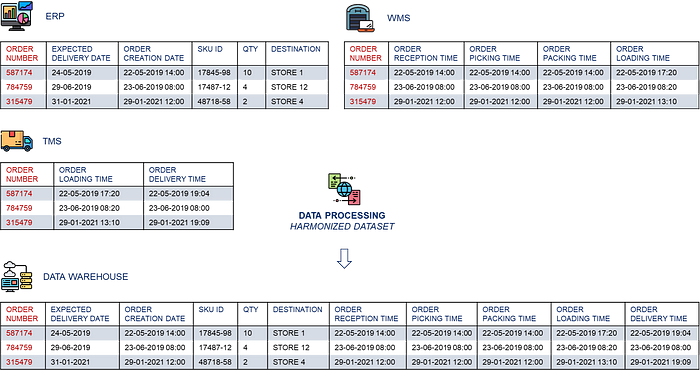

The challenge is to collect and process transactional data

- From different systems that may not communicate with each other

Factory Management Systems vs. Warehouse Management Systems - With different formats (Unstructured vs. Structured)

Excel Utility Usage Reports vs. WMS Transactional Database(s)

💡 Data analysts and engineers can implement pipelines using a central data warehouse to collect and process raw data to feed LCA calculations.

The final result can be a self-service database of harmonized tables containing transactional records covering the full cycle from raw material collection to store delivery.

💡 For more details,

Your sustainability department can then use these tables to run calculations and estimate the resource usage or CO2 emissions of each process.

What can we do to reduce our environmental footprint?

Data Analytics for Solution Design

Now that you have automated the Life Cycle Assessment, your sustainability team has been able to set the baseline.

The total CO2 emissions for 2022 are 75k Tons Co2eq.

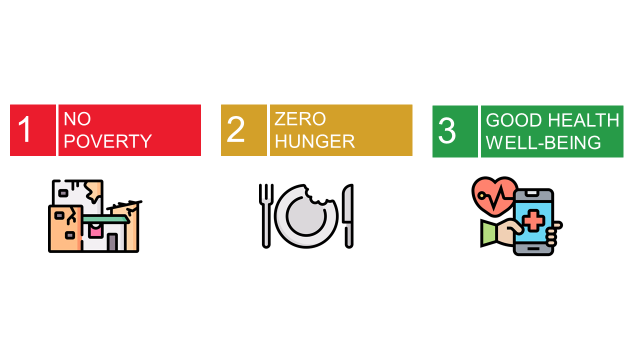

Following the United Nations Sustainable Development Goals (SDG), your company committed to a 30% reduction by 2023.

The next step is to build a roadmap to reach this target.

I have previously shared data-driven methodologies to implement decarbonization initiatives

- Sustainable Sourcing: select the set of suppliers that minimizes the environmental impact of your raw materials sourcing

- Sustainable Supply Chain Optimization: design an optimal network of factories and warehouses to minimize the emissions

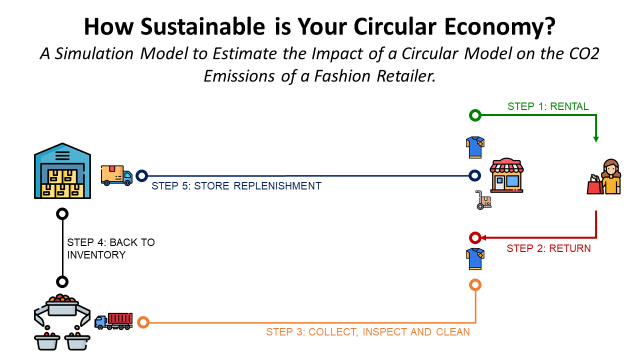

- Circular Economy: create a logistic chain to collect and reuse returned items from customers to save raw materials

Implementing a circular model can provide the highest carbon emissions reductions as it directly impacts the product.

However, the case studies above were mainly focusing on the generation of insightful prescriptions using advanced analytics.

Now that your model told us what to do. How can you support the implementation?

Because such a transition can completely disrupt your current supply chain operations, Logistics operations will expect support to ensure a smooth implementation and avoid disrupting the business or impacting profitability.

In the next section, we will see how data science can support this operational transformation.

Overcoming the Operational Challenges

While the shift to a circular economy looks promising, it comes with various operational challenges.

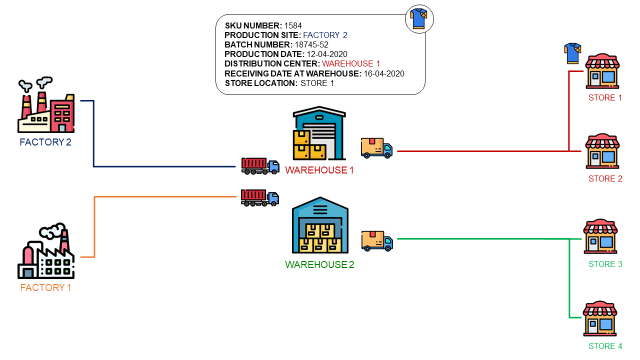

The Opacity of Supply Chain Networks

This is the major barrier to the transition towards a circular economy.

In traditional linear economies, the origin and journey of goods from raw materials to the final product are often obscure.

Your company might not have a clear understanding of its supply chain beyond their immediate suppliers and customers.

- Can you track the production facility of any item sold in your stores?

- Can you link a finished product leaving the factory with thefor the identification of inefficiencies, provides traceability to customers, batch of raw materials used to manufacture it?

A lack of transparency makes it difficult to trace products back to their source.

This is creating a stumbling block in adopting circular economic practices.

In a circular economy, understanding the lifecycle of a product (from raw materials to disposal) is crucial for implementing efficient recycling and reusing strategies.

With opacity, we cannot ensure that materials are being sourced sustainably, used efficiently and recycled properly.

You might also be missing opportunities to reduce waste, streamline operations and use resources more efficiently

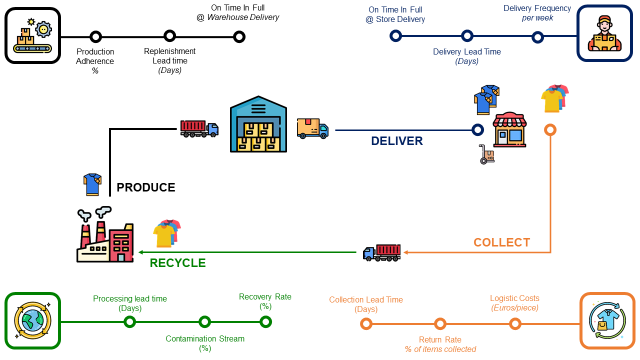

An optimal circular economy would require a minimum set of performance indicators like

- Tracking of production and transportation KPIs with

Production Adherence (%), Replenishment Lead Time (Days) - Measuring the performance of reverse logistics with

Logistic Costs (Euros/piece), Ratio of Returned Items (%) and Collection Lead Time (Days) - Identifying potential improvements for the recycling process with Recovery Rate (%), Contamination Stream (%) and Processing Lead Time (Days)

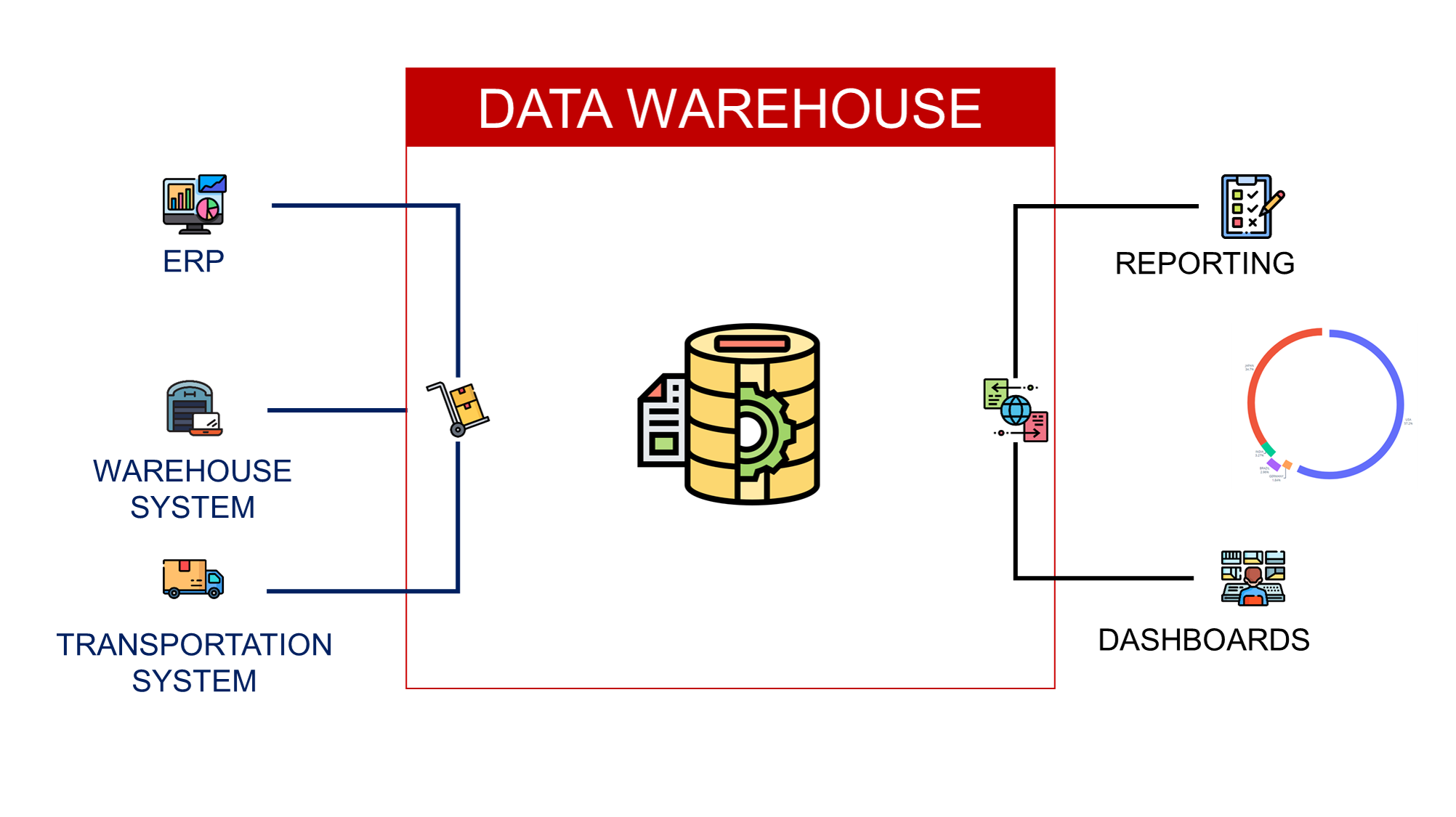

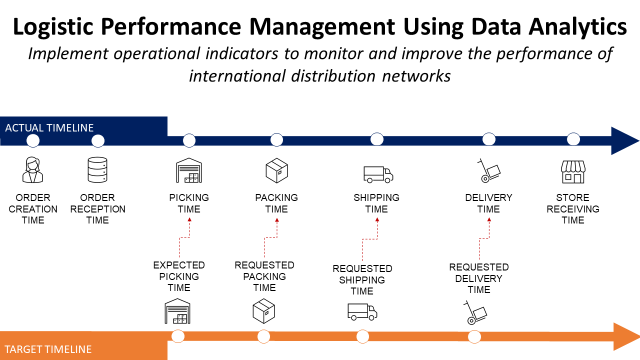

These KPIs, covering logistics and manufacturing, require data from multiple systems with different data formats and database structures.

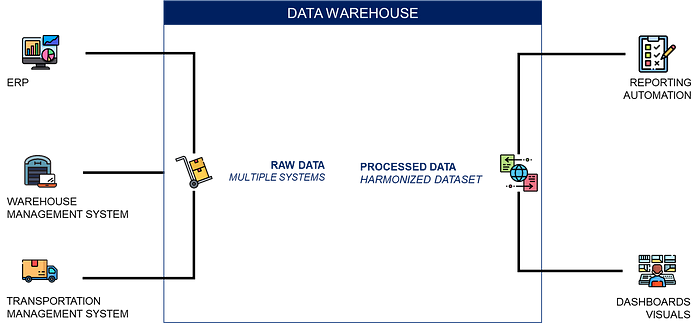

💡 Your team can play a crucial role in addressing these issues by

- Connecting to systems that track your products along the value chain and gathering data with timestamps

- Store and process this data to create a central source of information that can be used to create reports, dashboards and optimization models

- Implement automated reporting tools with KPIs designed by Supply Chain and Sustainability teams

This comprehensive view allows for the identification of inefficiencies, provides traceability to customers, and facilitates the transition.

💡 For more analytics solutions for supply chain traceability,

The Low Residual Value of Used Products

In our existing linear economy, products are designed for consumption and disposal but not for reuse or recycling.

The product residual value refers to the remaining worth of a product after it has been used and has completed its initial lifecycle.

Once used, these products often have little residual value.

How can we design a profitable circular model?

Therefore, the costs associated with collecting used products for recycling often outweigh the value of the materials recovered.

This endangers the economic viability of circular business models and discourages businesses from transitioning.

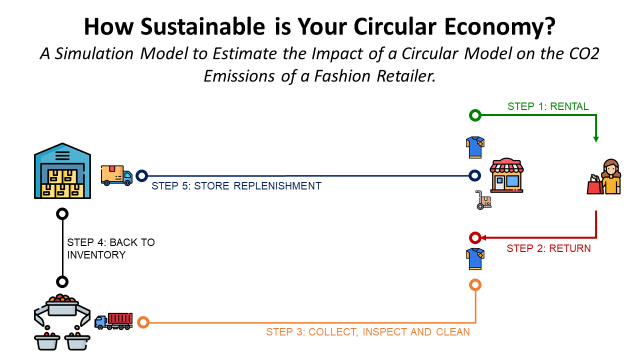

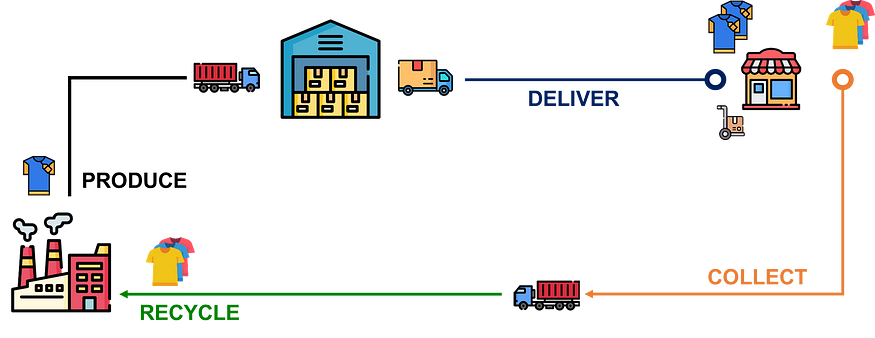

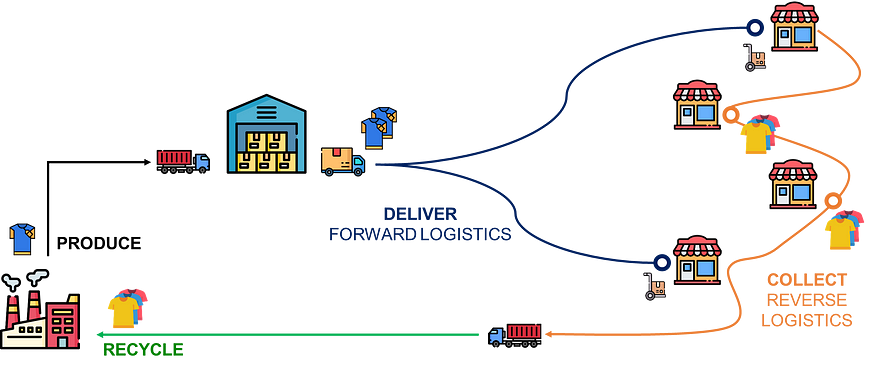

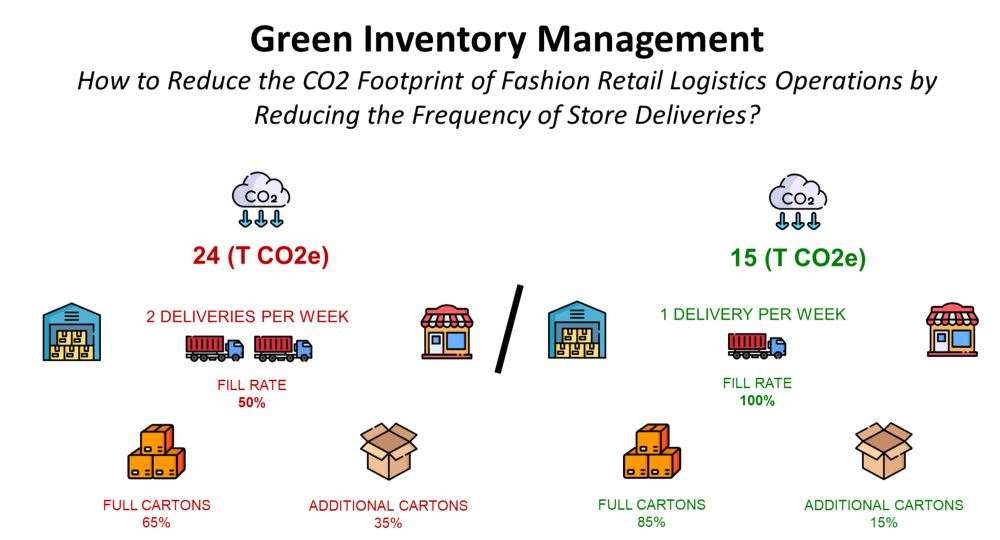

For instance, if we take the example of our T-shirt

- Forward Logistics is cost-efficient as we are delivering t-shirts by full containers with large trucks using optimized routing

- Reverse Logistics in comparison, is extremely expensive as we collect used garments by piece with complex sorting and recycling flows that require customized processes

As reverse logistics operations can become extremely complex, it’s easy to face the situation that recycling becomes more expensive than disposal.

💡 Data analytics can play a crucial role in addressing these issues

- Streamline reverse logistics operations using optimization models to minimize the cost of collection and sorting of used items

- Designing alternative business models like subscription models for which items are rented instead of sold

With these additional simulation models, you can support the implementation of a profitable reverse flow to recycle (or reuse) your products.

Material Efficiency & Recycled Materials Usage

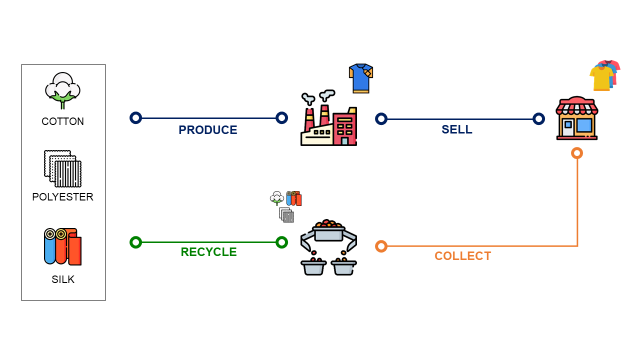

As we move towards a circular model, material efficiency becomes a predominant concern.

Making products with fewer materials and minimizing waste in production processes can bring substantial economic and environmental benefits.

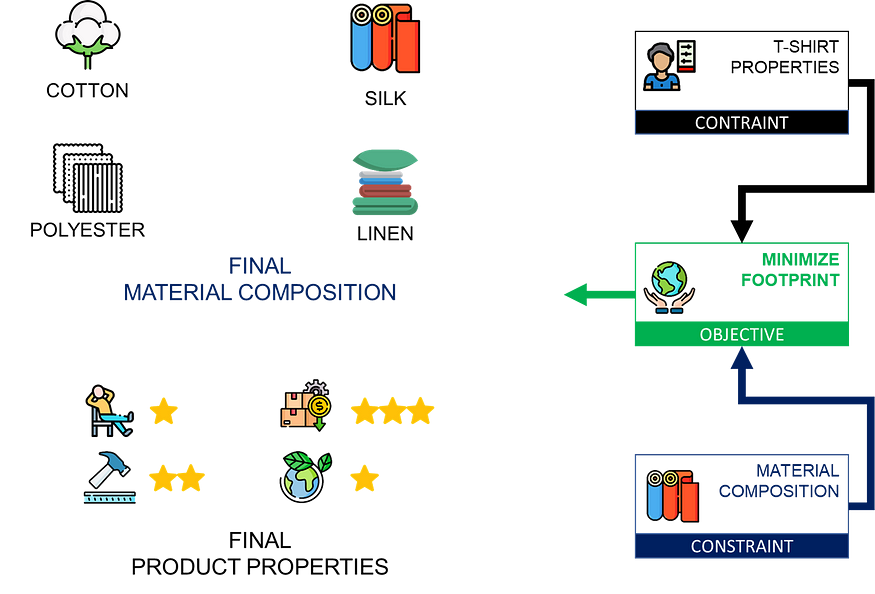

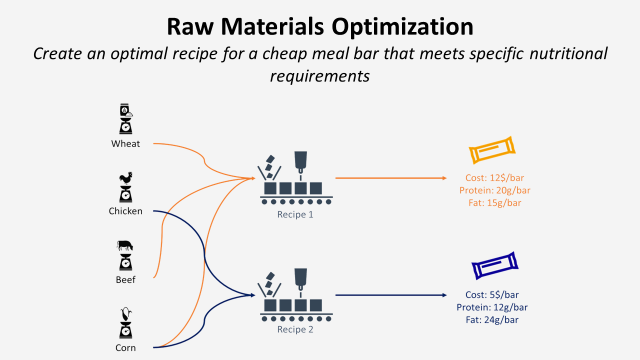

Raw Material Optimization with Linear Programming

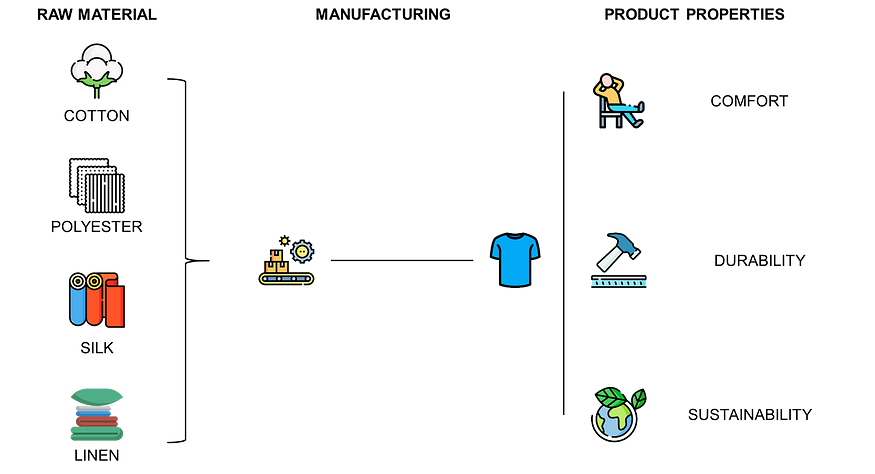

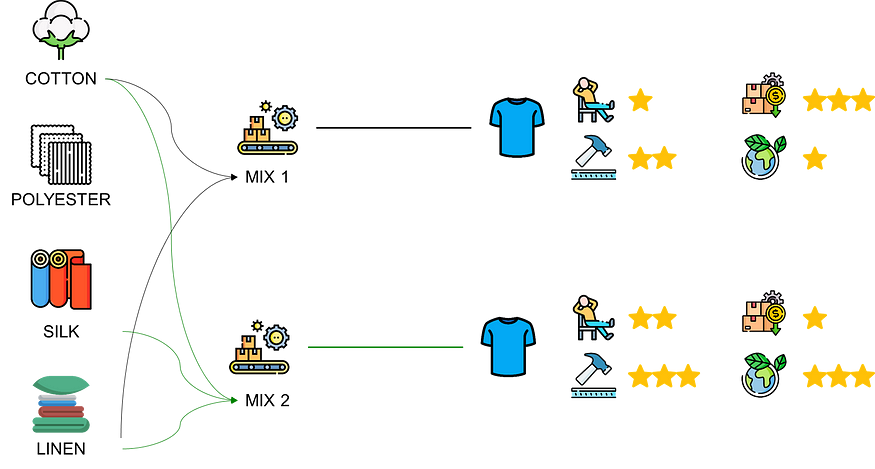

Efficient use of materials can drastically reduce waste and support the usage sustainable use of resources.

There are different types of fabrics at our disposal, including cotton, polyester, linen and silk.

Each type of fabric has different costs and attributes, such as durability, comfort and environmental impact.

The goal of the manufacturer is to minimize the overall cost of production while meeting the necessary quality and sustainability standards.

What is the best mix to meet our profitability and sustainability goals?

This is a multi-dimensional optimization problem where we are trying to optimize for cost and sustainability under certain constraints.

Example of T-shirt manufacturing

Let us imagine a scenario in which the T-shirt must contain

- At least 40% cotton for comfort

- Not more than 30% polyester due to sustainability guidelines

- Silk must not exceed 10% of the total material

This problem can be modelled and solved using linear (or non-linear) optimization with Python.

- Parameters: The quantity of each raw material used to produce a T-shirt

- Constraints: the one listed above

- Objective function: minimize environmental footprint, minimize the cost or a mix of both

Your team can use libraries like PuLP or SciPy to create an optimization model for testing several objective functions and eventually find the perfect mix of materials.

💡 For more details,

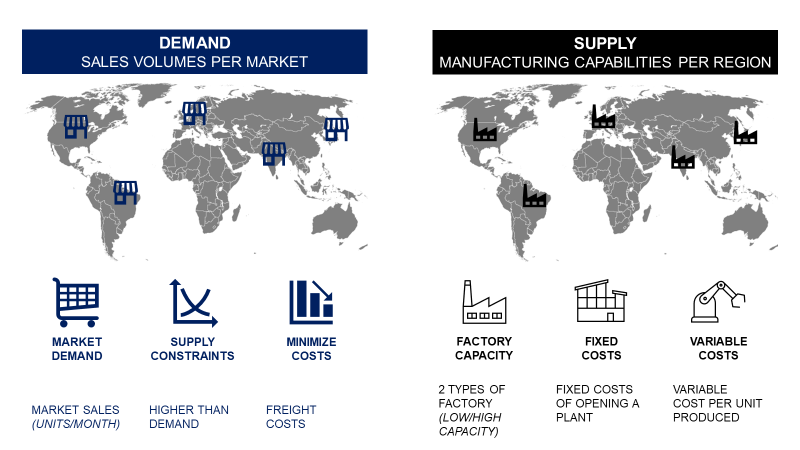

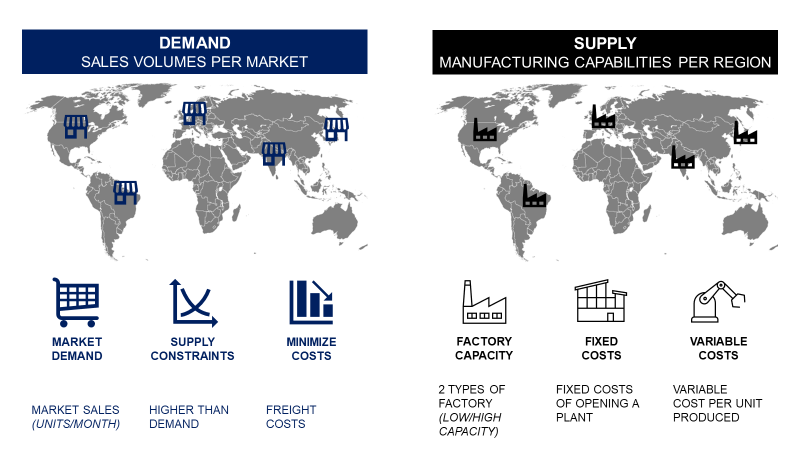

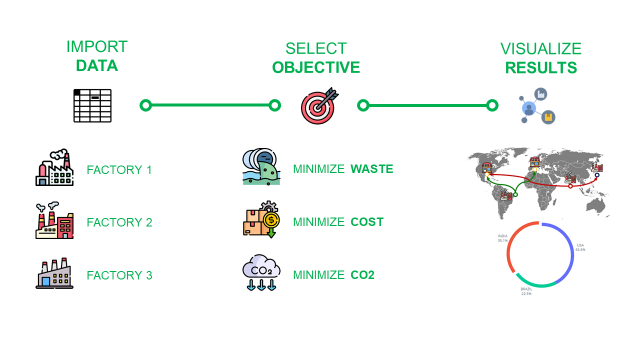

Supply Chain Network Optimization

To introduce reverse flow processes for recycling, we have to completely redefine our supply chain network.

Supply chain optimization can help us to make the best use of data analytics to find the optimal combination of factories, distribution and recycling centres that minimize cost impacts.

A linear programming model with Python can help us by

- Selecting the right locations for our recycling centres

- Optimizing the flows of used items collection

- Sizing the capacity of sorting and recycling centres

The objective is to minimize the cost of collecting, sorting and recycling used items to have a profitable and sustainable circular model.

💡 For more details on how to create a network optimization model,

Conclusion

The journey into the circular economy and its intersection with data science revealed interesting insights.

Data science can be a powerful enabler in transitioning towards a profitable circular economy by overcoming complex barriers and optimising resources.

In the future, we can expect analytics teams to play a pivotal role in the transition of companies to circular models.

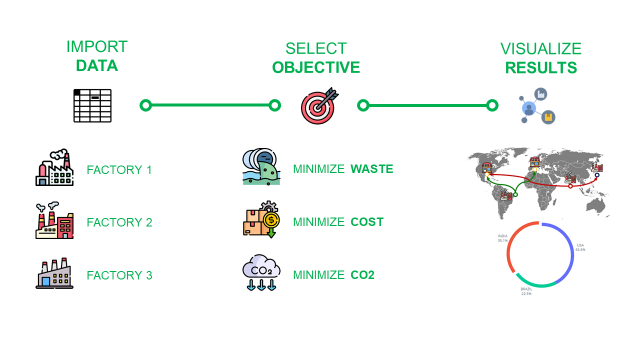

Deploy your tools on web applications.

A great way to support the implementation of data-driven prescription is to provide easy access to the model to anyone in the organization.

An easy to productize your model is to deploy it on a web application that can be used by operational and business people.

I have done the exercise of deploying three models, which I have presented in my articles using the VIKTOR platform.

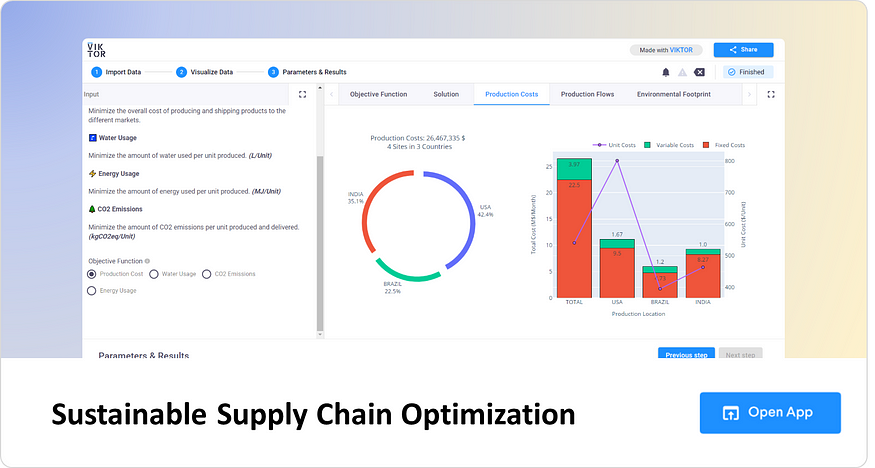

Sustainable Supply Chain Optimization Web App

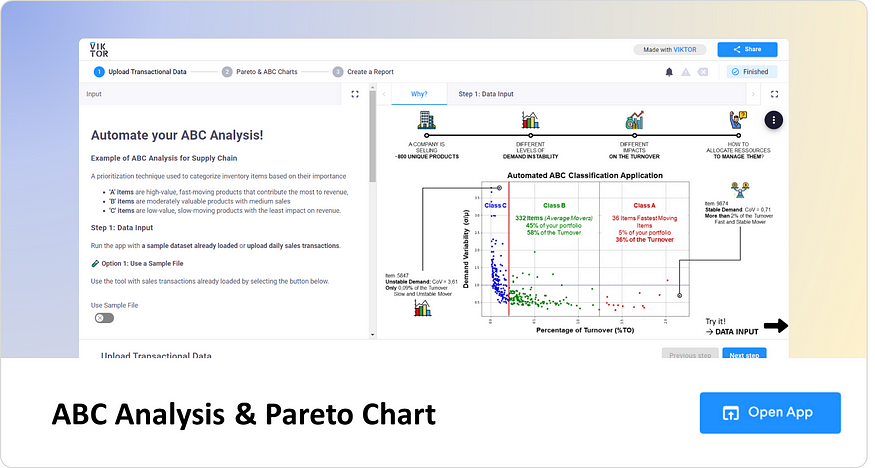

ABC Analysis and Pareto Chart Application

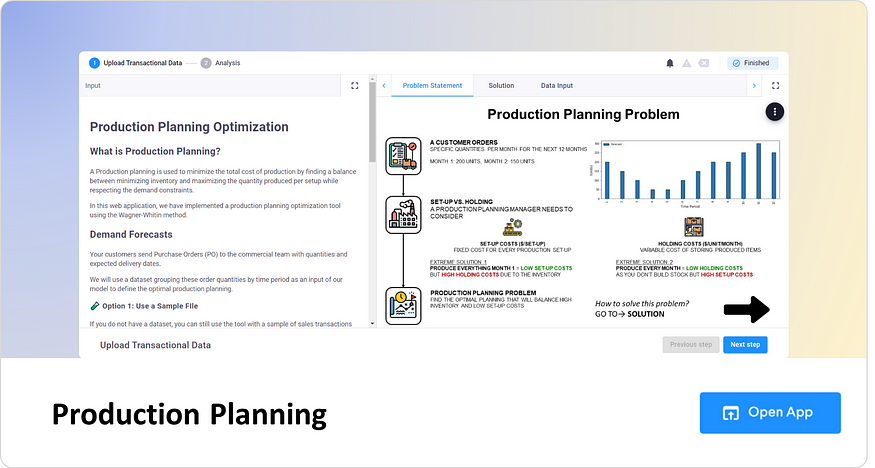

Production Planning

💡 For more details on how to deploy web apps with VIKTOR,

Go Beyond

The main focus here was on flow optimization.

However, other potential areas for exploration include

- Machine learning to predict and optimize resource usage

- Automation of waste sorting for recycling

- Predictive maintenance of goods for extended lifecycles

About Me

Let’s connect on Linkedin and Twitter, I am a Supply Chain Engineer using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, feel free to contact me.