Lean Six Sigma with Python — Chi-Squared Test

Perform a Chi-Squared Test to explain a shortage of drivers impacting your transportation network

Perform a Chi-Squared Test to explain a shortage of drivers impacting your transportation network

Article originally published on Medium.

Lean Six Sigma is a method that can be defined as a stepwise approach to process improvements.

In a previous article, we used the Kruskal-Wallis Test to verify the hypothesis that specific training positively impacts operators' Inbound VAS productivity. (Link)

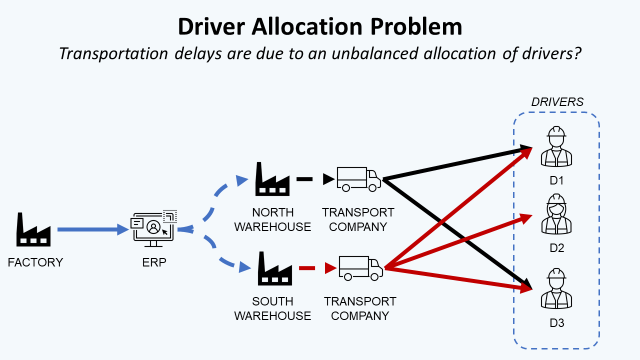

In this article, we will implement the Chi-Squared Test with Python to understand if transportation delays are due to a bad allocation of drivers.

💌 New articles straight in your inbox for free: Newsletter

I. Problem Statement

Transportation delays are due to drivers' allocation issues?

II. Data Analysis

1. Exploratory Data Analysis

Analysis with Python sample data from historical records

2. Perform Cross Tabulation

Summarise the relationship between several categorical variables.

3. Pearson’s Chi-Square Test

Validate that your results are significant and not due to random fluctuation

III. Conclusion

I. Problem Statement

1. Scenario

You are the Inbound Transportation Manager of a small factory in the United States.

Your transportation network is simple, you have two routes:

- Route 1: coming from your northern regional hub (with difficult road conditions and busy traffic)

- Route 2: coming from your southern regional hub (with no traffic and a beautiful modern road)

Transportation is managed by an external service provider with a fleet of three trucks (with three different drivers: D1, D2, D3).

Replenishment Process

- The Factory sends a replenishment order to your ERP

- The Southern regional hub receives the order first

- If the stock in the southern hub is too low then the order is transferred to the northern hub

- ERP sends a pick-up request to the transportation service provider (From Selected Hub to Factory)

- The first driver accepting the request is delivering the raw materials to the factory

P.S: As a customer, we do not have any visibility on the process of driver allocation.

Problem

When an order is allocated to the northern regional hub the lead time to get the request accepted is 35% higher than the southern hub.

Question

Are there drivers avoiding as much as possible to be allocated to the north route?

Experiment

We have analyzed the shipments of the last 18 months to build a sample of 269 records.

II. Data Analysis

1. Exploratory Data Analysis

2. Perform Cross Tabulation

A cross-tabulation of the data can provide some insights and help us to discover a potential pattern in the repartition of driver’s allocation.

Example

82.65 % of shipments handled by Driver 1 are from SOUTH HUB

Example

38.89 % of shipments from SOUTH HUB are handled by Driver 1

3. Pearson’s Chi-Squared Test

The first table is called also called a Contingency table. It is used in statistics to summarise the relationship between several categorical variables.

We’ll calculate the significance factor to determine whether the relation between the variables is of considerable significance using the Chi-Squared Test.

Conclusion

Because the p-value >0.05, there is no significant proof that the driver’s allocation is linked to the Hub.

Code

III. Conclusion

This analysis helped us to refute our initial feeling that some drivers deliberately avoid the northern hub.

Therefore, we need to perform a deeper root cause analysis to understand why we have a longer lead time to find a driver for replenishment from this hub.

About Me

Let’s connect on Linkedin and Twitter, I am a Supply Chain Engineer that is using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, feel free to contact me.