Lean Six Sigma with Python — Kruskal Wallis Test

How to replace Minitab with Python to perform Kruskal Wallis Test evaluating the impact of training on warehouse operators’ productivity

fiveLean Six Sigma (LSS) is a method based on a stepwise approach to process improvements.

This approach usually follows five steps (Define, Measure, Analyze, Improve and Control) for improving existing process problems with unknown causes.

In this article, we will explore how Python can replace Minitab (Software widely used by LSS experts) in the Analysis step to test hypotheses and understand what could improve the performance metrics of a specific process.

💌 New articles straight to your inbox for free: Newsletter

I. Problem Statement

Can we improve the operators' productivity by giving them a training designed by R&D team?

II. Data Analysis

1. Exploratory Data Analysis

Analysis with Python sample data from experiments with operators

2. Analysis of Variance (ANOVA)

Verify the hypothesis that training impacts productivityANOVA assumptions are not verified

3. Kruskal-Wallis test

Confirm that the hypothesis can be generalized

III. Conclusion

Problem Statement

Scenario

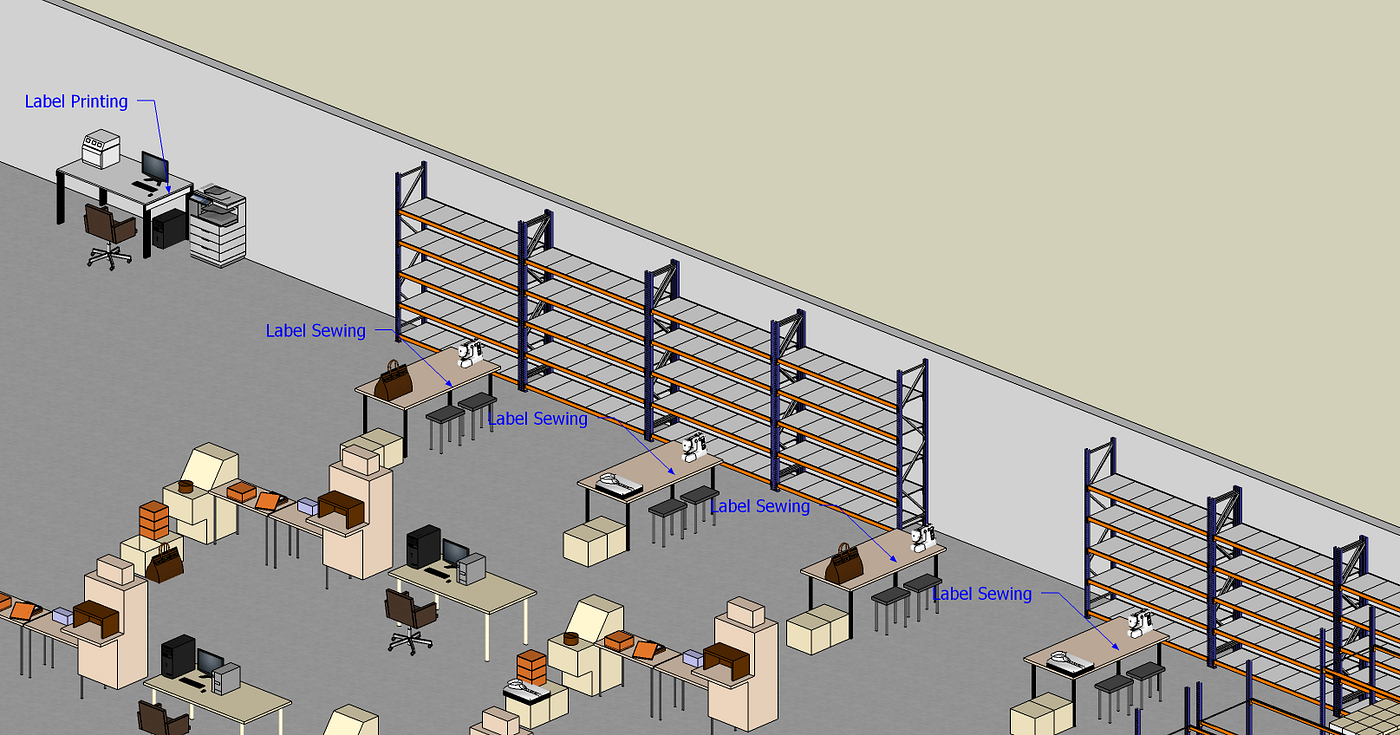

You are the Continuous Improvement Manager of a Distribution Center (DC) for an iconic Luxury Maison focusing on Fashion, Fragrances and Watches.

The warehouse receives garments that require final assembling and value-added service (VAS) during the inbound process.

For each dress received, your operators need to print a label in the local language and perform label sewing.

In this article, we will focus on the improvement of label sewing productivity. Labels are distributed to the operators in batches of 30 labels.

The productivity is calculated based on the time (in seconds) needed to finish a batch.

Edit: You can find a Youtube version of this article with animations in the link below.

Impact of training your workforce

With the support of the R&D team, you designed training for the VAS operators to improve their productivity and reduce quality issues.

Question

Does the training have a positive impact on the productivity of operators?

Hypothesis

The training has a positive impact on the productivity of VAS operators.

Experiment

Randomly select operators and measure the time per batch (Time to finish a batch of 30 labels in seconds) to build a sample of 56 records.

Data Analysis

Exploratory Data Analysis

You can download the results of this experiment in this CSV file to run the whole code on your computer (here).

56 records

35 records of operators without training

21 records of operators with training

Box Plot

Based on the sample data, we observe that the median and mean are considerably lower for operators who received training.

Hypothesis

The training reduces the average time per batch.

CodeMinitab

Analysis of Variance (ANOVA)

In this scenario, we want to check if the training (Variable X) is impacting the total time per batch (Variable Y).

Because X is a categorical variable (Training = Yes/No) and Y is numerical, the appropriate method is ANOVA.

ANOVA is a statistical method used to check if we can generalize the difference of means seen in the sample data to the entire population.

Step 1: Calculate the p-value

ddof: 11

ddof: 245.267

F: 17.1066

p-unc: 0.000151308

p: 20.173692

p-value is below 5%

CodeMinitab

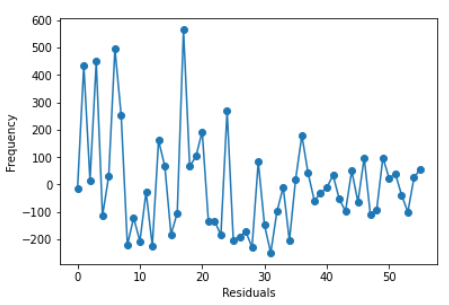

Step 2: Validate the assumptions of ANOVA

Based on the p-value, we know that the difference of mean is real and not due to random fluctuation.

However, before jumping to a conclusion we need to check that the ANOVA assumptions are satisfied

- Residuals are naturally distributed

Answer: No

- There are no outliers or irregularities

Answer: No

Conclusion

ANOVA requirements are not met, we need another method to confirm that the training actually impacts operators' productivity.

CodeMinitab

Kruskal-Wallis test

If your sample data fails to meet ANOVA requirements, you can use Kruskal-Wallis Test to check if the difference in means is due to random fluctuation.

pvalue = 1.205e-13

p-value is below 5%

Conclusion

The p-value is below 5% so we can conclude that the difference of means is statistically significant.

We can confirm that the training has a positive impact on the productivity of the operators.

CodeMinitab

Conclusion

This data-driven approach gave you enough elements to convince your management to invest in workforce training.

You brought enough insights with a moderate effort of experimentation by generalising patterns from sample data using statistics.

About Me

Let’s connect on Linkedin and Twitter, I am a Supply Chain Engineer that is using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, feel free to contact me.