Lean Six Sigma with Python — Logistic Regression

Replace Minitab with Python to perform a Logistic Regression to estimate the minimum bonus needed to reach 75% of a productivity target

Lean Six Sigma is a method that can be defined as a stepwise approach to process improvements.

In a previous article, we used the Kruskal-Wallis Test to verify the hypothesis that a specific training positively impacts operators' Inbound VAS productivity.

In this article, we will implement Logistic Regression with Python to estimate the impact of a daily productivity bonus on your warehouse operators picking productivity.

💌 New articles straight in your inbox for free: Newsletter

I. Problem Statement

What should be the minimum amount of daily incentive to get 75% of workers that reach their productivity target?

II. Data Analysis

1. Exploratory Data Analysis

Analysis with Python sample data from the experiment

2. Fitted Line Plot of your Logistic Regression

What is the probability of reaching the target for each value of the daily incentive?

3. Validation with the p-value

Validate that your results are significant and not due to random fluctuation

III. Conclusion

Problem Statement

Scenario

You are the Regional Director of a Logistic Company (3PL) and you have 22 warehouses in your scope.

In each warehouse, the site manager has fixed a picking productivity target for the operators; your objective is to find the right incentive policy to reach 75% of this target.

P.S: Picking Productivity is defined by the number of cartons picked per hour paid.

Find the right incentive policy

Currently, productive operators (operators that reach their daily productivity target) receive 5 euros per day in addition to their daily salary of 64 euros (after-tax).

However, this incentive policy applied in 2 warehouses is not that effective; only 20% of the operators are reaching this target.

Question

What should be the minimum daily bonus needed to reach 75% of the picking productivity target?

Experiment

- Randomly select operators in your 22 warehouses

- Implement a daily incentive amount varying between 1 to 20 euros

- Check if the operators reached their target

Edit: You can find a Youtube version of this article with animations in the link below.

Data Analysis

Exploratory Data Analysis

You can find the full code in this Github (Follow Me :D) repository: Link.

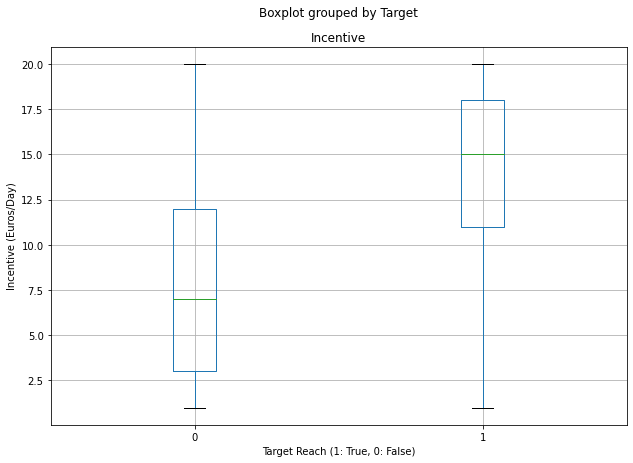

Box plot of the sample distribution

The median value of incentive for reached target’s day is more than 2 times higher than the one for the days below this target.

Fitted Line Plot of your Logistic Regression

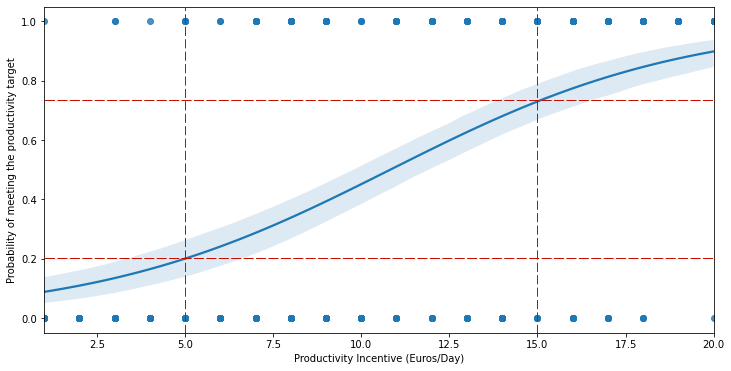

Logistic Regression will provide us with a probability plot. We can estimate the probability of reaching the target for each value of the daily incentive.

Confirmation of the current trend: 5 euros -> 20% of the productivity target reached

We need at leat 15 euros incentive per day to ensure 75% of probability to reach the target

CodeMinitab

Validation with the p-value

In order to check that these results, based on sample data, are significant we need to compute the p-value.p-value: 2.1327739857133364e-141

p-value < 5%

The p-value is below 5% so we can conclude that the difference of means is statistically significant.

Conclusion

If you fix a value of 15 euros per day of incentives, you will reach 75% of your target.

CodeMinitab

Conclusion

What is the ROI?

Based on this experiment, we have fixed a minimum amount of 15 euros/day for the bonus incentives to reach 75% of your productivity target.

Before implementing this new incentive policy you need to check that you have a positive return on investment:

- What is the total cost to company (CTC)(Basic Salary + Social Contributions) per hour paid for picking operators? (Euros/Hour)

- What is the total amount of hours earned after the productivity increase? (Hours)

- What would be the CTC of hiring temporary workers for this number of hours? (Euros)

- What is the total CTC of incentives?

After answering these questions, you’ll be able to estimate the return on investment for, this new incentive policy. Depending on the hourly cost of the operators, you may lose or save money.

Next Steps

However, the operator's productivity may not be only driven by their motivation but can also be, you’ll be able to estimate the return on investment for impacted by the warehouse layout, the picking process or the order profile.

Therefore, this analysis should be completed with a process optimisation study to ensure that operators can exploit their full potential, motivated by the right amount of incentives.

About Me

Let’s connect on LinkedIn and Twitter, I am a Supply Chain Engineer that is using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, feel free to contact me.