Supply Chain Sustainability Reporting with Python

4 steps to build an ESG reporting focusing on CO2 emissions of your Distribution Network

4 steps to build an ESG reporting focusing on CO2 emissions of your Distribution Network

Article originally published on Medium.

The demand for transparency in sustainable development from investors and customers has grown over the years.

Investors have placed an increased emphasis on the sustainability of the business when assessing the value and resiliency of an organization.

Therefore, more and more organizations invest resources to build capabilities for sustainability reporting and determine the best strategies for a sustainable supply chain.

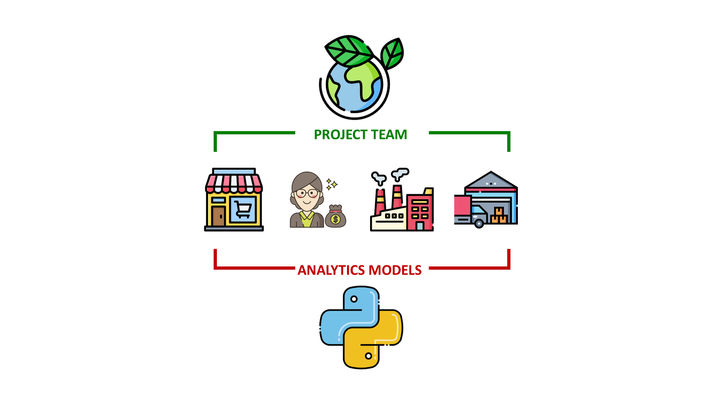

In this article, we will introduce a simple methodology to report the CO2 emissions of your Distribution Network using Python and PowerBI.

💌 New articles straight in your inbox for free: Newsletter

CO2 Emissions Formula for Transportation

Calculate the CO2 emissions of multi-modal transportation.

II. Data Processing with Python

List of the datasets needed to build your report

1. Import Shipped Order Lines

All the purchased orders of your customers that have been shipped

2. Add Unit of Measure Conversions

Merge with Master Data to convert quantities in weight

3. Distances Collections

Collect the distances by transportation mode

III. CO2 Calculation

1. Final Calculation of the CO2 Emissions

2. What can you do if you have missing data?

VI. Example of visualization using PowerBI

Edit: You can find a Youtube version of this article with animations in the link below.

CO2 Emissions Formula for Transportation

Definition

Based on the GHG Protocol corporate standard (Link), greenhouse gas emissions are classified into three scopes:

- Scope 1: direct emissions released to the atmosphere because of company’s activities (Company’s facilities like manufacturing plant/warehouses, company’s vehicles)

- Scope 2: indirect emissions from the generation of purchased energy

(purchased electricity, gas, ..) - Scope 3: all indirect emissions (out of scope 2) occurring in the value chain of the company (Transportation, Waste of Operations, Business Travels, …)

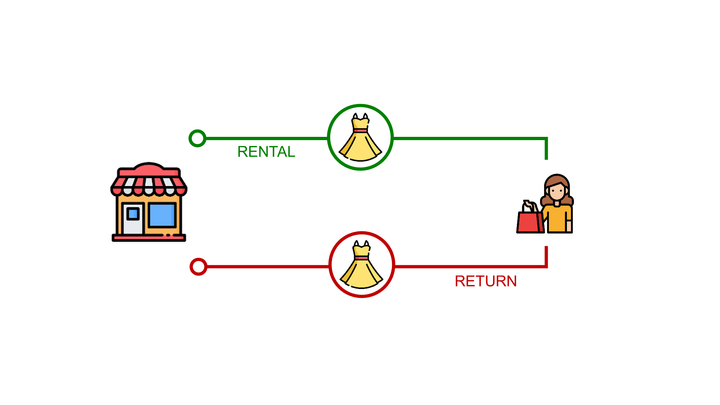

In this article, we will focus our attention on the Scope 3 calculations related to downstream transportation.

What is the environmental impact of your distribution network?

Formula

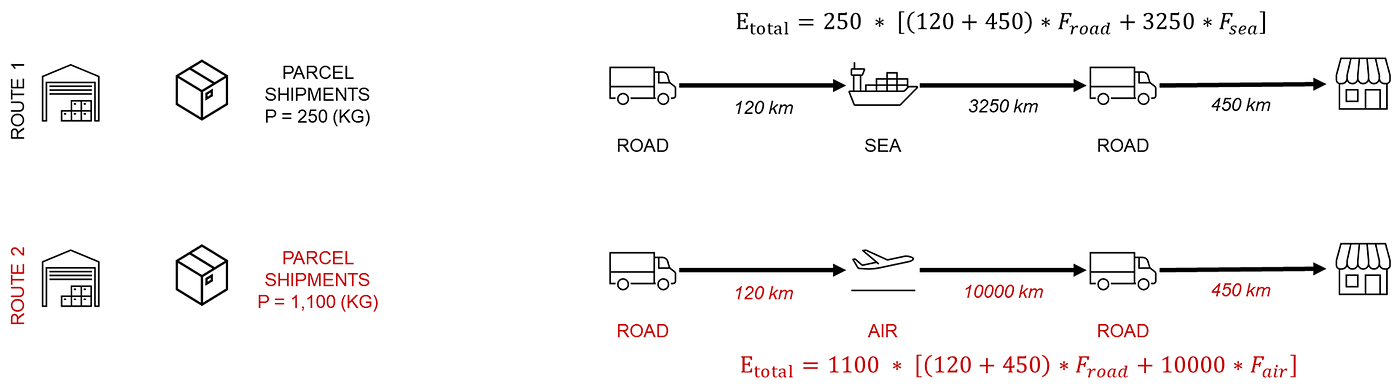

Following the protocol of the French Environmental Agency Ademe (Link), the formula to estimate the CO2 emissions of transportation is:

With,

This formula provides a gross estimation of the CO2 emissions without requiring a high level of granularity of transportation data.

A more accurate approach would be to estimate the CO2 emissions of each delivery considering the model of the vehicle (truck, container carrier, plane or train) and the filling rate.

II. Data Processing with Python

Based on this formula, we can now start to collect data to calculate the emissions.

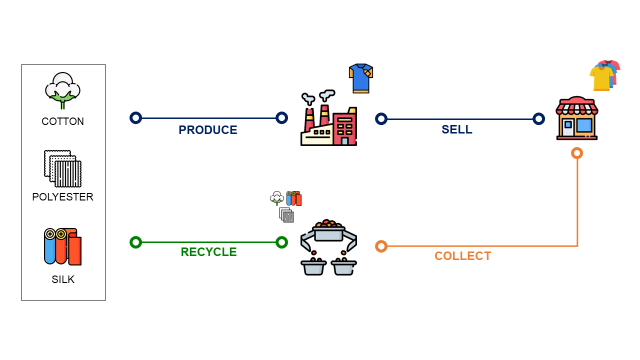

Import Shipped Order Lines

Let‘s start by extracting from our ERP (or WMS) the shipped order lines: all purchased orders of your customers that have been shipped from your warehouses.

This dataset includes

- Order information: Order Number, Line Number

- Item Code: Identification number of the item in the master data

- Warehouse Code: the business unit from where these orders are shipped (Distribution Center, Factory)

- Customer Code: the final destination where the orders are delivered (Store, Distribution Center)

Code

Result

Add Unit of Measure Conversions

The next step is to convert the quantities ordered into weight (kg).

Net Weight vs. Total Weight

Before going into the details of the calculation, we need to explain the difference between gross and net weight.

Packaging is the container used to cover your finished product. In some ERP’s master data, you may find the net weight (without packaging) and the gross weight (with packaging).

For this report, we need to make sure to take the gross weight to estimate the total weight including packaging.

Handling Unit (Cartons, Pallet)

Depending on the order quantity, your customer can order by unit, cartons (grouping several units) or pallets (grouping several cartons).

If you are lucky enough to have the weights of cartons or pallets, you can use them if your customer is ordering full cases or full pallets.

Assumption of Mixed Cartons

For certain logistic operations, where you need to perform piece picking (Luxury, Cosmetics, E-Commerce), the quantity per order line is so low that you rarely ship full cartons.

In this case, there is no point in using full cartons weight; we can only rely on the total weight per unit. For our example, we will assume that we are in this situation.

Code

Results

Distances Collections and GPS Locations

We need to collect the distance by mode:

- Air Freight

- Sea Freight

- Road Transportation: Trucks

- Rail Transportation: Trains

We will also add the GPS locations of the destination for our PowerBI reporting.

Code

III. CO2 Calculation

1. Final Calculation of the CO2 Emissions

We have now all the information needed to be gathered in a single DataFrame. We can start to calculate the CO2 emissions using emissions factors associated with your transportation network.

Sum the weight by Order

For reporting purposes, let us calculate the CO2 emissions for each order number (linked with a customer and a date).

Final Results

2. What if you don’t have 100% of the distances?

A major challenge here is to get the distances if you have several thousand delivery locations.

If you are not able to collect 100% of the distance from your carriers, you can:

- Get the road distances using Google Maps API

- Estimate the distance using the Haversine formula

- Compute the average distance of your top customers (in Euros) and apply the average to the locations without distances

3. What if you don’t have 100% of the weight conversions?

In some cases, the master data is not updated and you cannot get the unit of measure conversions for all the items.

In that case, you can

- Focus your data collection efforts on the high runners (turnover)

- Estimate the weight per euro for these items (kg/euros)

- Apply the average ratio on the c remaining items without conversions to get their weight

VI. Example of visualization using PowerBI

Bubble map with size = f(CO2 Total)

Visual Insights

You can observe where you have the majority of CO2 emissions (large bubbles) with a colour coding by transportation mode.

Split by Country Destination and Item Code

Product Portfolio Insights

For each market, which item has the highest environmental impact?

CO2 = f(Turnover) by City Destination

Financial Insights

The impacts of your future efforts for CO2 Emissions reductions on the profitability will probably be higher for the customers in PEINE-WOLTORF.

Next Steps

After measuring your emissions, a potential next step could be to optimize your Distribution Network using a methodology presented in the article below.

About Me

Let’s connect on Linkedin and Twitter data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, please contact me.