Transportation Network Analysis with Graph Theory

Use graph theory to optimize the road transportation network of a retail company

Use graph theory to optimize the road transportation network of a retail company

Article originally published on Medium.

Objective

Build graphical representations of a road transportation network to support optimization studies.

Introduction

For a retailer, road transportation to deliver stores represents a major part of the logistics costs.

Companies often conduct route planning optimization studies to reduce these costs and improve the efficiency of their network.

It requires collaboration between continuous improvement engineers and the transportation teams that manage operations daily.

In this article, we will use Graph Theory to design visual representations of a transportation network to support this collaboration and facilitate solution design.

💌 New articles straight in your inbox for free: Newsletter

I. Distribution Network

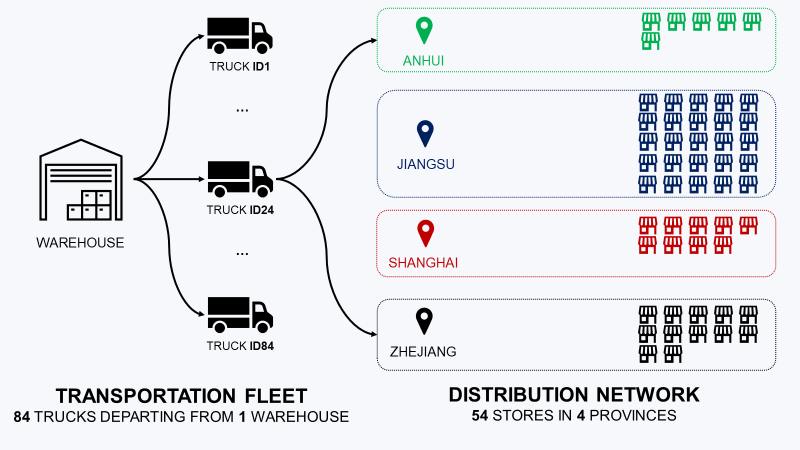

Distribution centre of a retail company with 54 stores

II. Problem Statement

Optimization of the route planning to reduce transportation costs

1. Exploratory Data Analysis

1 year of deliveries to 50 stores

2. Multi-Store Delivery

Use dedicated trucks to deliver several stores

III. Solution using Graph Visualization

1. Visualization using the Graph Theory

What are the stores that are delivered together?

2. Challenge the current routing

Collaborate with the Transportation Planner to expand the routes

IV. Conclusion & Next Steps

If you prefer watching, have a look a the Youtube tutorial

Distribution Network

Context

As a continuous improvement engineer of a retail company, you are in charge of reengineering warehousing and transportation operations.

In your scope, you have a major distribution centre located in Shanghai (China) that delivers 54 hypermarkets.

Delivery by Truck

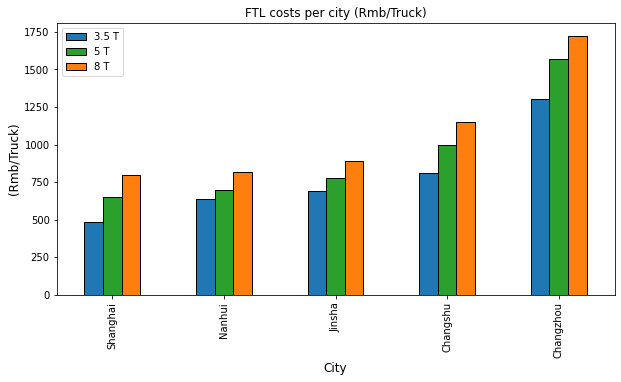

These stores, located in four different provinces, are delivered using 3rd party transportation service providers.

They provide trucks with three different capacities (3.5 Tons, 5 Tons, 8 Tons).

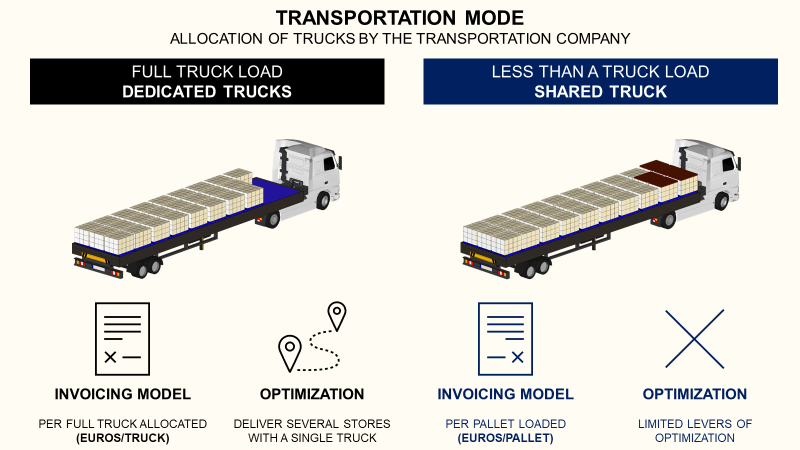

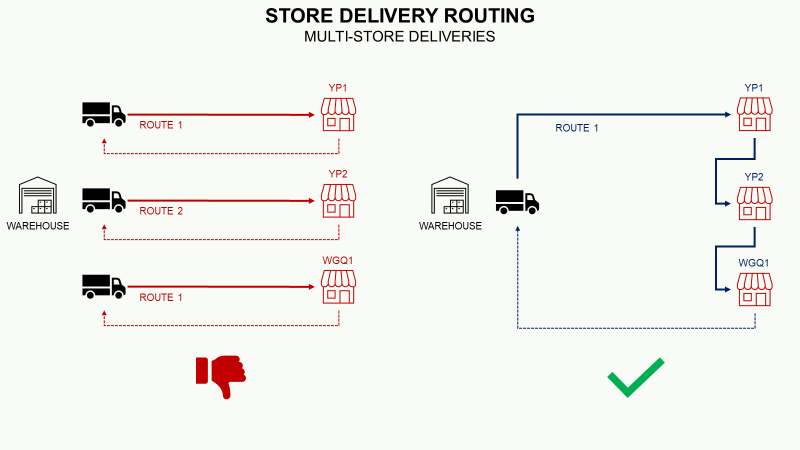

Based on the routing and loading plans designed by the transportation planners, a dedicated truck is allocated to deliver stores.

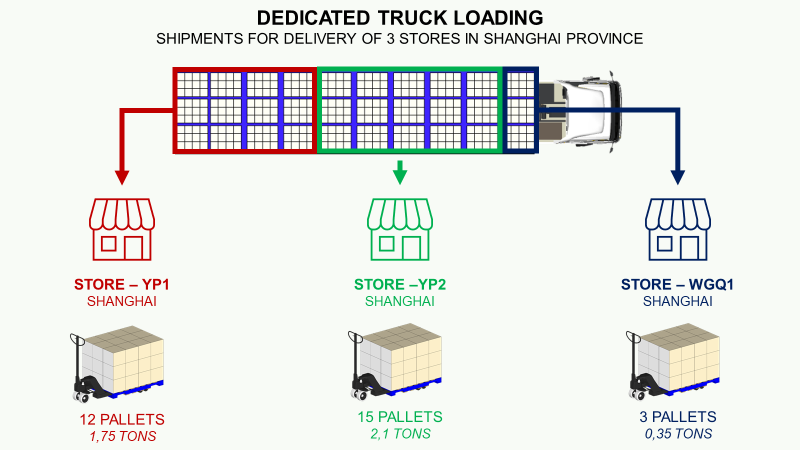

Loading Plan Example

Let’s imagine a scenario with three stores in Shanghai that ordered a total of 30 pallets (5 T).

- The warehouse team prepares the orders and puts the cartons on pallets

- The transport planner decides to deliver these three stores with a single 5T truck

- Pallets are loaded into the truck

You are invoiced by the carrier using a price per truck (Rmb/Truck) based on the first city delivered onsingle store routes as possible the route.

For the delivery of these three stores in Shanghai

Cost = 650 (Rmb)

The role of your transportation planning team is to design routes to ensure that your trucks are full when they leave the warehouse.

Therefore, they avoid as many single store routes as possible to maximize the filling rate.

If you want to know more about the FTL Transportation

Problem Statement

Objective

Your objective is to reduce the total cost of transportation.

Insights: Cost per Ton

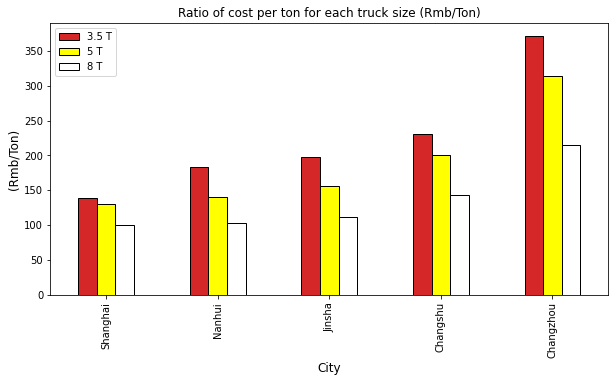

A major lever of optimization is the size of trucks.

If you increase the average size of the trucks, you reduce the overall cost per ton. A good method is to deliver more stores per route.

Exploratory Data Analysis

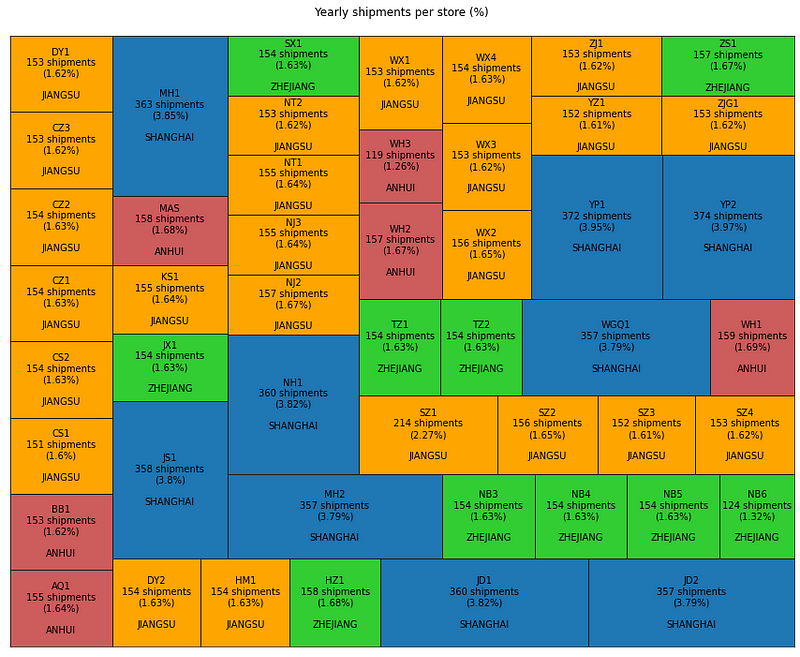

You have 12 months of shipments to understand the current routing.

Number of shipments per store

A majority of the deliveries are in Shanghai and the neighbouring province of Jiangsu.

Trucks size

Except in Shanghai, where you have large hypermarkets driving a large part of the demand, the other provinces have stores of relatively the same size.

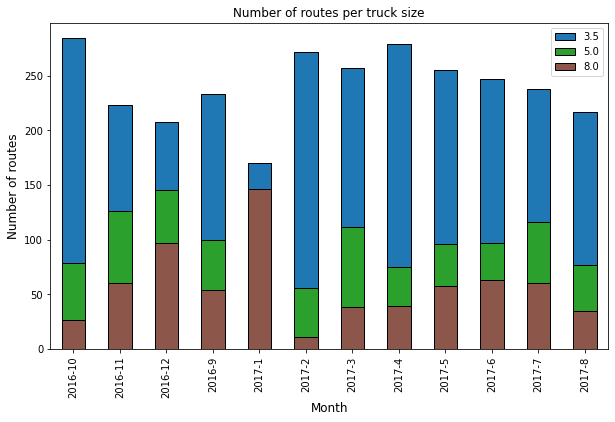

Number of routes per truck size

Except in January, the peak season before the Chinese New Year, the majority of routes are delivered using small trucks.

Solution using Graph Visualization

The objective is to design a new transportation plan to increase the average size of trucks by delivering more stores per route.

Constraints

Because of operational limitations, you need to respect the constraints below

- Delivery Time Window: stores can receive products only at a certain time of the day

- Road Restrictions: large trucks are forbidden on some roads

- Unloading Conditions: some stores need to be delivered first

Visual Support for Collaboration

Because of these operational constraints, you cannot perform this analysis alone.

It is key to collaborate with the transportation teams that have experience managing the route planning daily.

Solution: Graph Theory

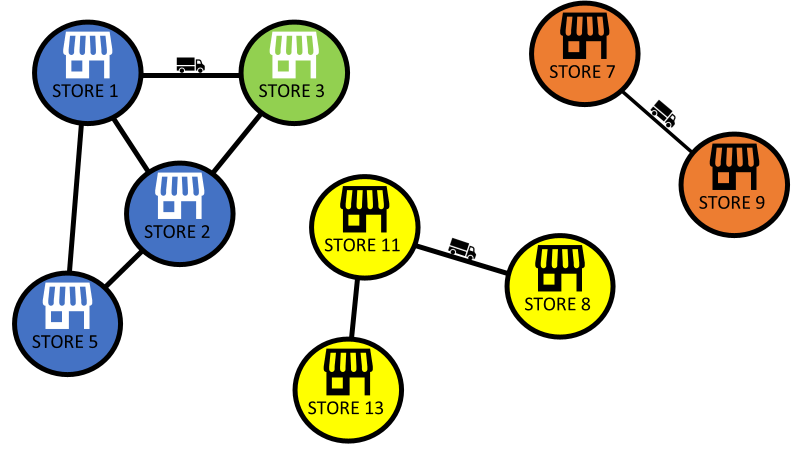

A graph is a structure that contains nodes (stores), and each of the related pairs of nodes is called an edge.

An edge of two stores means that these stores have been delivered together at least one time.

For instance, store 2 has been delivered with store 3, store 5 and store 1.

Question

With the current routing, which stores are delivered together?

Challenge the current routing

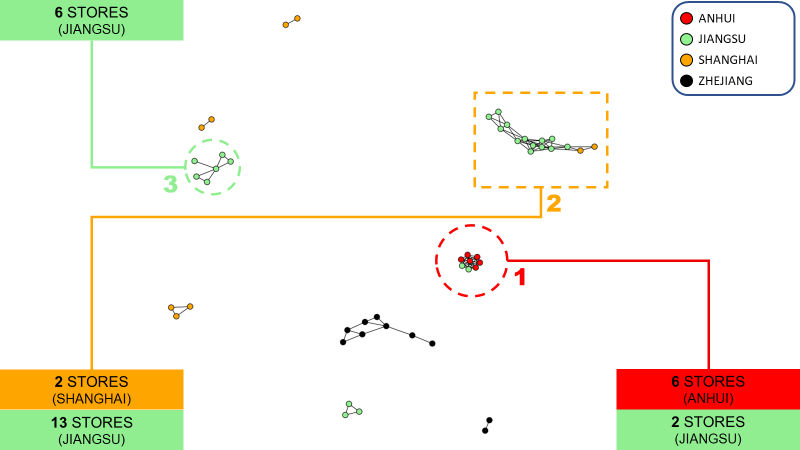

Let’s have a look at the results with the current routing.

Example: Full-year scope

You can find different types of clusters

- Type 1: stores are all interconnected and usually represent a single route (it is good to group several stores in one route)

- Type 2: stores are sequentially connected, creating a chain

- Type 3: 1 store is connected to all the other stores

This visual can support discussions with the transportation team

- Why do we have two isolated stores in Zhejiang?

- Can we increase the average truck size if we group the two isolated pairs of Shanghai?

- Can we have more type 1 clusters?

Question

What is the impact of truck size?

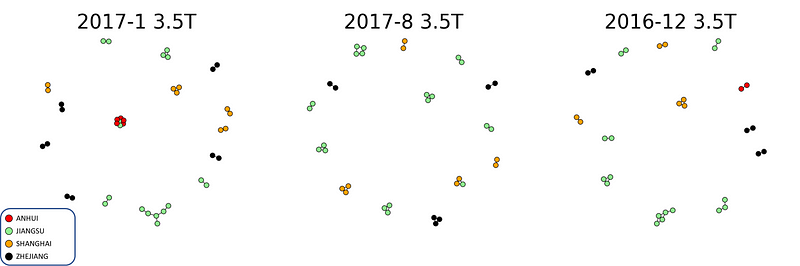

Example: 3.5 T trucks only

Our main issue is the high proportion of small trucks in our fleet.

Network Graph of 3.5T trucks

There are fewer interconnections for these routes. There are no major clusters of interconnected nodes.

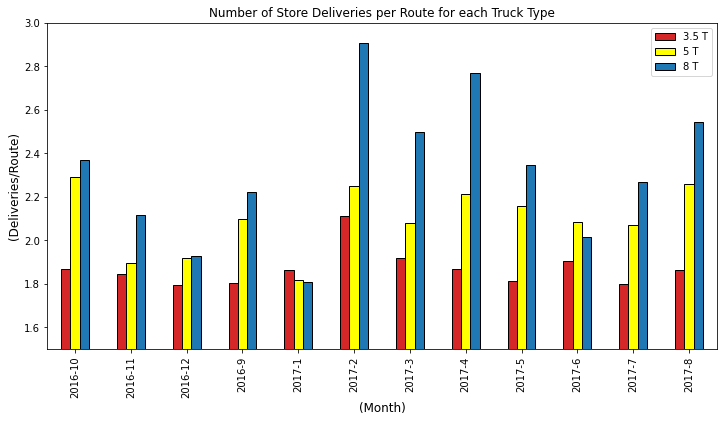

Average Truck Size

The observation is confirmed when you look at the average number of deliveries per route for each truck size.

Except during the Chinese New Year peak period, large trucks have a higher number of deliveries per route.

Question

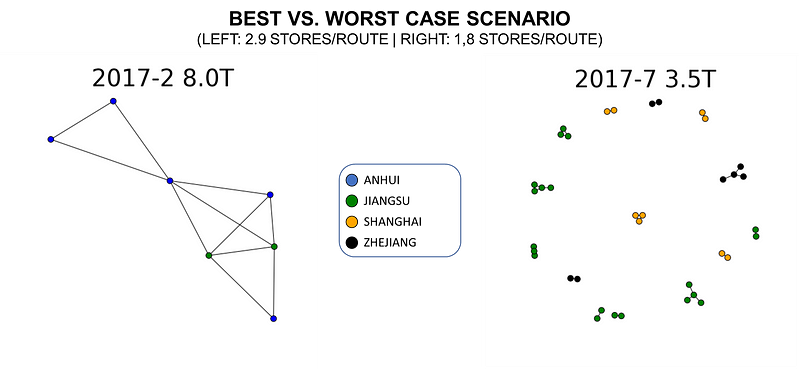

What is the difference between the lowest vs. highest ratio of stores per route?

For the best scenario (left), stores are highly interconnected (up to 4 connections). The contrast is clear with the other network which is highly fragmented.

Conclusion & Next Steps

Conclusion

This tool provides a visual representation of the distribution network to support collaborative work between you and the transportation teams.

Next Steps

Based on your analysis, you can propose potential improvements (grouping additional stores, merging routes) and assess the operational feasibility with teams.

This analysis is the beginning of the study.

Each of the potential solutions needs to be validated by operations and store managers to ensure a smooth implementation.

About Me

Let’s connect on Linkedin and Twitter, I am a Supply Chain Engineer that is using data analytics to improve logistics operations and reduce costs.

If you’re looking for tailored consulting solutions to optimize your supply chain and meet sustainability goals, feel free to contact me.